additonal silicon rubber for tire mold making

- US $13.29

200 - 40,000 kilogram

- US $9.58

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelmedical grade silicone,medical grade silicone,sili

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 17:26:02 GMT

Paramtents

Color Translucent

Certificate MSDS, SGS, RoHS , Reach , ISO

Shape Pasty

Package Vacuum Pumping

Shelf Life 12 months

Mix Ratio 1: 1

Pot Life 30-40 mins

Cure time 3-4 hours

MOQ 200kgs

Samples Available

Packging & Delivery

Min Order200 kilogram

Briefing

Easy Operation

High transparent

Large quantity

Fast delivery

Detailed

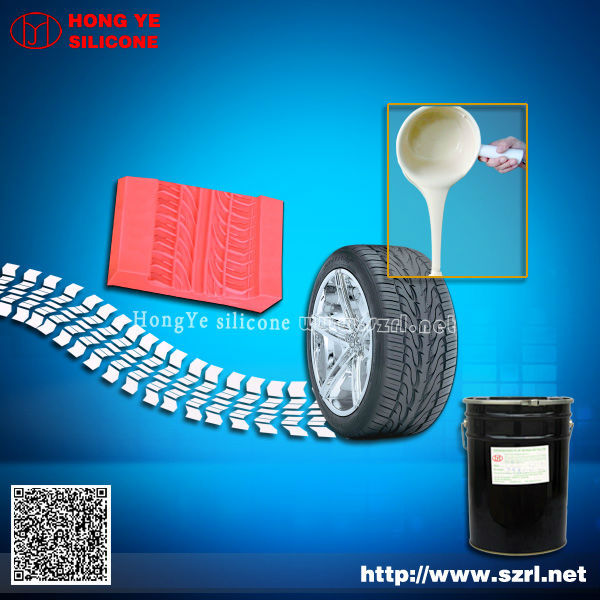

additonal silicon rubber for tire mold making

Description of additonal silicon rubber for tire mold making:

additonal silicon rubber for tire mold making is generally named as two-part addition silicone rubber that vulcanises at room temperature.Part A is a flowable liquid, part B is the curing agent(platinum catalyst). It features an exceptional fluidity ,good operability,excellent physical properties and very low shrinkage. The mixing ratio between Part A and Part B can be 10:1 or 1:1.

Main application of additonal silicon rubber for tire mold making:

- Rapid prototyping (urethane casting/silicone tooling/vacuum casting)

- Concrete moulding /cement products

- PU resin casting

- General Mouldmaking

- Superior manual mold design

Main properties of additonal silicon rubber for tire mold making:

- almost nil shrinkage

- high chemical resistance to aggressive components of some types of resins

- good tear strength (this feature ensures higher resistance to wearing and shearing)

- high degree of precision in reproduction

- high dimensional stability over time and non-deformability

- high resistance to high temperatures and ageing (resit to -60-200°C)

- excellent non-stick effect

- environmental, odorless and nontoxic

E-625 silicone rubber standard datasheet(25°C)

Model | Color | Mixing ratio | Pot life (mins) | Demould time ( hrs) | Hardness ( A0 ) | Tensile strength (MPa) | Tear-strength (kN/m) | Mixed Viscosity (mPas) | Shrinkage rate (%) | Elongation (%) |

E-625 | Light transparent | 1:1 or 10:1 |

30-40

| 3-4hrs(25°C) 20-30mins(60°C) | 25±2 | ≥ 5.5 | ≥ 15 | 8000 | ≤0.1% | 500% |

Notice of additonal silicon rubber for tire mold making:

Addition silicone is forbidden to mix with organic compounds of condensation cure silicone rubber,otherwise, the silicone rubber will not cure, and also should not mix with organic compounds containing S, P, N as well as metallic salt of organic acids. It also will cause this product cure uncompletely or not cure.

additonal silicon rubber for tire mold making instructions:

Rapid prototyping for instance,a master model that usually originates from stereolithography or selective laser.If you make silicone molds in pouring way,please follow below steps:

Storage ,shelf life and handling precautions:

1. Shelf life can be twelve(12) months when stored at 25°C in tightly closed original packages.

2. Storage beyond the expired date does not necessarily mean that the product is no longer

usable. In this case , the properties required for the intended use must be checked for quality assurance reasons.

3,The curing agent may denature if the cap is left off after opening.Make sure to tightly seal the products prior to storage.Take particular care under conditions of high temperature or humidity.

4,If any of these products should come into contact with skin,wipe the exposed area with a cloth and then wash it thoroughly with soap.

5. This kind of product is non-dangerous product, which could be transported as general products.

Need any more information about additonal silicon rubber for tire mold making, pease feel free to contact with Miss Caroline

TEL: +86-755-89948019

Mobile: +86-18938867567

Skype: cathy19900719

Email: hysf(at)szrl(dot)net

Website : www(dot)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents