buy molding silicone for our scented candle making

- US $13.60

200 - 40,000 kilogram

- US $5.91

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-E642# silicon rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 18:04:54 GMT

Paramtents

Grade Standard Industrial Grade,Food Grade

Appearance Fluid

Application Industrial Mold Making Materials

colour customized

certificates SGS RoHS

material silicone

usage making mold

origin shenzhen

payment T/T W/U L/C

sample available

type liquid

hardness customized

MOQ 200KG

Packging & Delivery

Min Order200 kilogram

Briefing

features: favorable hardness, light viscosity low shrinkage

Detailed

buy molding silicone for our scented candle making

Applications,

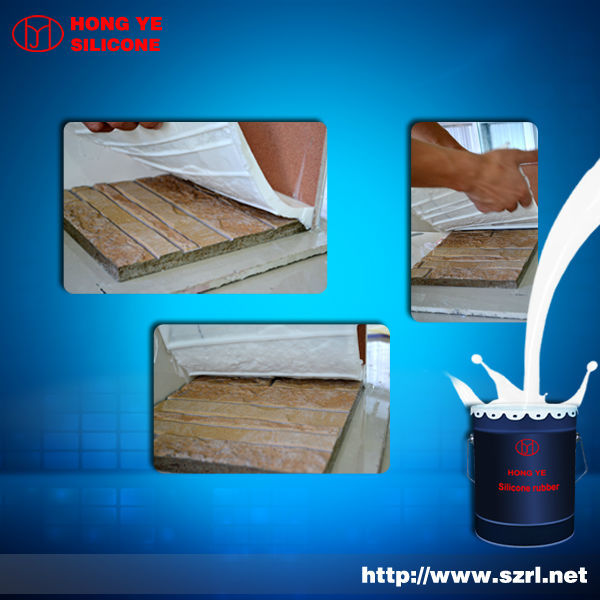

HY- E642# addition molding silicone could be mainly used for making concrete stones, precision molds, PU molds, prototyping, for life casting, fabric finishing, seal for electronic components and solar circuit board, trademark decoration. etc.

Description

HY- E642# addition molding silicone is generally named two-components silicone rubber, Part A is a flowable liquid, part B is the curing agent. It features an exceptional fluidity and good operability. The mixing ratio is 1:1,mainly be suitable for making FDA molds application.

Technique Data of HY-E642# molding silicone

Model | HY-E642# |

Appearance | Translucent or white |

Mixing Ratio | 1:1 |

Operating time (Mins 25°C) | 30-50 |

Curing time (Mins 25°C) | 3-4h |

Hardness (A°) | 42±2 |

Density ( g/cm 3 ) | 1.08 |

Viscosity (CS) (Part A) | 30000 ± 5000 |

Viscosity (CS) (Part B) | 5000 ± 500 |

Viscosity (CS) (After mixed) | 10000 ± 2000 |

Tensile-strength( kgf /cm2 ) | 100 ± 20 |

Tear-strength (kgf /cm2 ) | >15 |

Elongation-break(%) | 350 ± 50 |

Retractility(%) | ≤0.1 |

Frequently asked questions of Molding silicon

Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

Need the datasheet and the price of Molding silicon for reference, please feel free to confirm some of your information in advance,

1) What's the material of your products, plaster, resin, cement, wax, or any others, please?

2) What is the size of your products, small(within 30cm), medium(30-60cm) or big(60-200cm), please?3) How about your way of making silicone mold, by pouring way or brushing way, please?

Getting your information in details, we will recommend the most suitable Molding silicon with the best price at the first time for your reference.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents