molding silicone rubber make resin crafts mold

- US $12.50

200 - 40,000 kilogram

- US $7.50

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-E635# Good price Silicone for Mold Making

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 18:26:41 GMT

Paramtents

color white

sample free

Model HY-E635

application for mold making

mix ratio 1:1

Appearance Translucent or white

Curing time 2-4h

Hardness (A°) 35±2

Density ( g/cm 3 ) 1.08

Viscosity (CS) (After mixed) 10000 ± 2000

Packging & Delivery

Min Order200 kilogram

Briefing

1 .Normally Curing agent arrange together as free charge 2.can be reused much

Detailed

molding silicone rubber make resin crafts mold tions

Specifica of molding silicone rubber make resin crafts mold tions

1. Silicona para moldes

2. Silicona with high molding times

3. Easy molding and mix

4. Excellent tear and tensile strength

Silicona para moldes application:

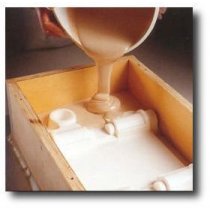

- Silicona para moldes will reproduce the finest detail .

- Silicona para moldes are suitable for a variety of industrial and art related applications including making molds for reproducing prototypes, furniture, sculpture and architectural elements.

- Silicona para moldes can also be used to cast a variety of materials including wax, gypsum, low melt alloys/metals and urethane, epoxy or polyester resins

Silicona para moldes feature:

- Silicona para moldes :flowable liquid silicon and curing agent.

- Silicona para moldes Cures at room temperature within 2-4 hours.

- An exceptional fluidity and good operability, easy to demold.

- Good tensile and tear strength, low shrinkage.

- High duplication times.

Why does the Silicona para moldes have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation. Thus, we should take the proper silicone rubber to make the mold for suitable products.

Any further information required ,pls contact Ms. Sarah

Tel: +86-755-8994 8019

Fax: +86-755-8994 8030

Mobile: +86-13620974715

Silicona para moldes; Silicona para moldes; Silicona para moldes; Silicona para moldes; Silicona para moldes; Silicona para moldes; Silicona para moldes; silicon para moldes; silicon liquido; silicon liquido; silicon liquido; silicon liquido;

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents