FDA addition cure silicone rubber for mold making

- US $15.78

200 - 40,000 kilogram

- US $12.88

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelE625# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 18:37:09 GMT

Paramtents

Appearance translucent

Origin Guangodng China

Quality Hign

HS Code 39100000

MOQ 200KG

Payment T/T L/C Western union

Package 25kg/drum 200kg/drum

Certifications RoHS, MSDS, SGS, ISO9001:2000

Packging & Delivery

Min Order200 kilogram

Briefing

two-component

liquid silicone rubber

food grade

favorable hardness

Detailed

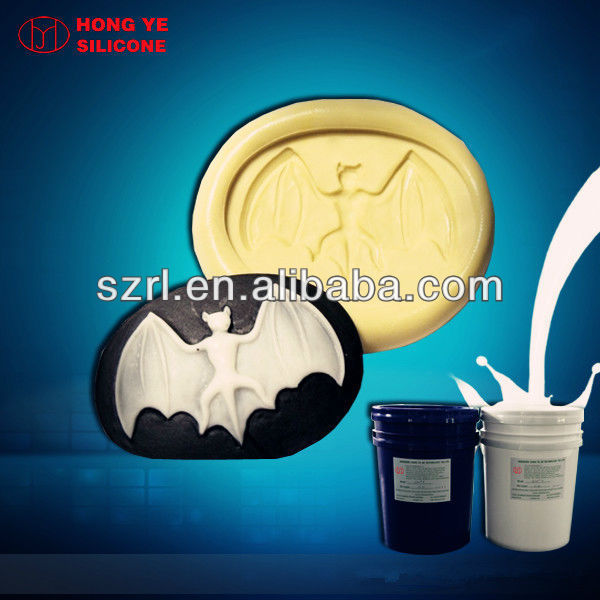

FDA addition cure silicone rubber for mold making Appilications |

Especially suitable for the molding

for plaster decoration duplication,

for gypsum sculpture reproduction,

for duplicating resin product with fine details,

for PU resin reproduction,

for wax molding,

for stone duplication ,

for epoxy moulds,

for pacrylic moulding,

for reproducing polyester craft

Some of the materials you can cast into a silicone mold are:

• Urethane Plastic

• Urethane Rubber

• Epoxy

• Polyester

• Fiberglass Resign

• Plaster

• Soap

• Wax

• Low melt metals (up to 400 degrees Max)

• HydroCal White

• UltraCal 30

• Rigid Foam

• concrete statue mold

| FDA addition cure silicone rubber for mold making Features |

/Good fluidity and good operability and good for pouring method.

/Excellent mechanical properties, in particular tear strength and tensile strength.

/Excellent flexibility and it is easy to demould.

/High temperature resistance, high duplication times and repeated use.

/There are a range of catalysts/curing agent/hardener allows the Liquid rtv silicone rubber to fulfill requirements for various applications and various requirements on the operation time and curing time.

| How to use FDA addition cure silicone rubber for mold making |

1.The cast pouring, for example:

Prepare a frame, fix the prototype for copy into the frame, (if the prototype’s material is glass or ceramic, the release agent is necessary to prevent sticking.

2. Take 1 part A and 1 part B,mix themevenly.

3.Vacuum defoaming in 1~3 min,inject the rubber into the type box, then vacuum defoaming again, curing 24 hours in nature room temperature, use it after demold.

4. Demold after 3 hours’ room temperature curing, and then use it after 24 hours’ keep mold under the same condition.

| Delivery/Postage/Payment |

Packing:5kg/pail,25kg/pail,200kg/pail

Delivery time is within 3 days after getting your bank receipt.

Payment Terms: T/T 100% in advance,L/C,Western Union

Mind order quantity(MOQ):200KG

Transport: by sea or by air

Shelf life:12 months under room temperature not open

Any more information, pls feel free to contact Bella at any time.

Mobile: 0086-18938867572

Tel: 0086-755-89948006

Fax: 0086-755-89948030

Website: www (dot) szrl (dot) net

Email:hysi(at)szrl(dot)net

Skype: bellajiaqi

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents