Addition cure silicone rubber for GRC products mold making manufacturer

- US $12.36

200 - 40,000 kilogram

- US $10.12

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelE-630

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 19:01:16 GMT

Paramtents

Color White

Curing agent 3%-5%

Certification SGS,MSDS,RoHS

Material 100% silicone

Appearance Fluid

Sample free

HS code 39100000

Port shenzhen

Application Addition cure silicone rubber for GRC products mold making

Packging & Delivery

Min Order200 kilogram

Briefing

2. high reproduction times

3. good tensile strength

4. exceptional fluidity

Detailed

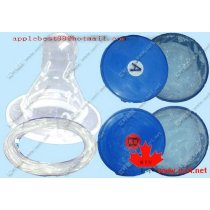

Applications of Addition cure silicone rubber for GRC products mold making:

Addition cure silicone rubber for GRC products mold making is a kind of food grade slicone rubber.It is primarily intended for cake mold,candy mold,chocolate mold and other food grade siliconemold,also intended for poly resin crafts, PU crafts, PU resin crafts, gypsum crafts, unsaturated resin crafts, lighting and candles crafts, plastic toy, stationery gifts crafts industry, a large statue Buddha, furniture, furniture decorative materials, statues Buddha, artifacts copied,

building decoration materials, largescale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Brief introduction of Addition cure silicone rubber for GRC products mold making:

Addition cure silicone rubber for GRC products mold making is mainly used for metallic art and crafts,babynipple,cake, candy food grade products mold making and so on. It is nontoxic and with very low shrinkage.

Features of Addition cure silicone rubber for GRC products mold making:

1. Two-component silicone rubber with platinum catalyst

2. Simple mixing ratio with 1:1 dosage

3. With high transparency, tensile strength, and tear strength.

4. Nontoxic & reach to Food grade

5. With good heat stability and weather ability ( temperature resistant range of -60-250 C)

6. With heat-ageing resistance

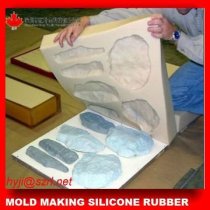

Picture show of Addition cure silicone rubber for GRC products mold making:

Datasheet of Addition cure silicone rubber for GRC products mold making:

Product | E-630 |

Appearance | Translucent |

Hardness(shore A) | 30±2 |

Mix ratio(A:B) | 1:1or 10:1 |

Viscocity Part A(mPa.s) | 20000±2000 |

Viscocity Part B(mPa.s) | 2400±500 |

Tensile strength (MPa) | 7.2 |

Tear-strength (kN/m) | 24 |

Elongation(%) | 440 |

Density | 1.13 |

Pot life/working time (mins) | 30-40 |

Curing time/setting time (hrs) | 3-4hrs(25°C) 20-30mins(60°C) |

Shrinkage rate (%) | 0.1 |

FAQ of Addition cure silicone rubber for GRC products mold making:

Why should the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Adding too much catalyst(curing agent).Too much catalyst can make the silicone cure very fast and and reduce the mold life.

C. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

Storage of Addition cure silicone rubber for GRC products mold making:

Addition cure silicoen rubber for GRC products mold making is an environment friendly liquid siliconeproducts, is not easy to burn and can be stored and transported as nonhazardous goods. The shelf life of the product is about 9 months from the date of production.

Inspection is required when exceeding the time limited. It can continue to be used in case of neither thickening nor deterioration.

Package of Addition cure silicone rubber for GRC products mold making:

5kg/drum, 20kg/drum and 200kg/drum

Shelf-life of Addition cure silicone rubber for GRC products mold making:

Twelve (12) months under room temperature 25 Celsius.

Certification of Addition cure silicone rubber for GRC products mold making:

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89948294

Mob:86-18938867593

E-mail: hysh(at)szrl(dot)net

Skype:kity-467707861

You can also send me e-mail by scanning 2 Dimensional Bar Code below:

About us:

We are manufacturer specializing in molding silicone rubber, mold duplicating rubber for resin craft makers, special silicon for manual molding, shoe mold rubber, pad printing silicone,

encapsulants and potting compound,addition cure liquid silicone,baby nipple silicone rubber ,lifecasting,food grade silicone rubber, trademark silicone rubber,

HTV silicone rubber, leadinc alloy crafts silicone rubber, hot stamping silicone plate, hot stamping silicone roller, gross rubber, RTV-2 silicone rubber, silicone molds, silicone products,etc.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents