Addition Cure Encapsulant and Potting Compound for Thermal Conductivity HY-9055#

- US $9.80

200 - 40,000 kilogram

- US $6.80

40,001 - 999,999 kilogram

group nameelectronic potting silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

model9055#

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 19:42:05 GMT

Paramtents

color as request

Packages 25kgs and 200kgs per drum

Application For moulds making

certificate RoHS, MSDS, SGS, ISO9001:2000

appearance liquid

sample available

mix ratio 1:1

hardness 55 shore A

operation time 30-45 mins under tempreature 25 degrees

shelf life 8-10 month

Packging & Delivery

Min Order200 kilogram

Briefing

Low shrinkage

Favorable tension

No deformation

Favorable hardness

Detailed

Addition Cure Encapsulant and Potting Compound for Thermal Conductivity HY-9055# Features & Applications

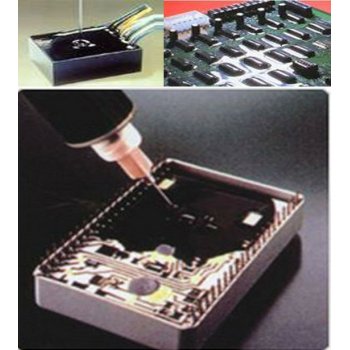

Addition cure encapsulant and potting compound for thermal conductivity HY-9055# is a two-component silicone rubber with low viscosity, which can be cured both at room temperature and high temperature.

Addition cure encapsulant and potting compound for thermal conductivity HY-9055# works on the surface of material as PC(Poly-carbonate), PP, ABS, PVC as to its superior bonding feature, and it is also applicable for insulation, waterproof, bonding of electronics parts.

Addition cure encapsulant and potting compound for thermal conductivity HY-9055# meets the requirements of European RoHs.

Addition Cure Encapsulant and Potting Compound for Thermal Conductivity HY-9055# Typical Application

- High-power electronic component.

- Power module and printed circuit board request thermal conductivity and high temperature.

Addition Cure Encapsulant and Potting Compound for Thermal Conductivity HY-9055# Technical Parameters

Properties index | Part A | Part B | |

Before Curing | Appearence | Dark Grey fluid | White fluid |

Viscosity (cps) | 2500+/-500 | 2500+/-500 | |

Features when operation | Mixing Ratio ( By weight) | 1:1 | |

Viscosity after Curing(cps) | 2000~3000 | ||

Operating Time (hr) | 2 | ||

Curing time ( hr, room temperature) | 8 | ||

Curing time ( min, 80C) | 20 | ||

Hardness(shore A) | 55+/-5 | ||

After Curing | Thermal Conductivity[W( m·K)] | ≥0.8 | |

Dielectric Strength( kV/mm) | ≥25 | ||

Dielectric permittivity(1.2MHz) | 3.0~3.3 | ||

Volume resistivity(Ω·cm) | ≥1.0×1016 | ||

Linear Dilatation[m/( m·K)] | ≤2.2×10-4 | ||

Fire Resistance | 94-V1 | ||

(Pls note all datas of addition cure encapsulant and potting compound for thermal conductivity HY-9055# above is in 25C with 55% humidity conditions. We don't guarantee a same date if testing under different conditions, or when data was regenerated).

Warm Tips

1. Sealing pakage for storage. The mixture should be used up at once to avoid wasting.

2. Silicone belongs to non-dangerous goods, but keep away form mouth and eyes.

3. When it gets stratified after a period of storage, Please mix HY-9055# evenly before using,

it does not affect the performance.

4. HY-9055# won’t be cured when mixed with some chemical material, so pls avoid contacting the following chemical materials

A. Organice tin compounds and silicone rubber with organotin

B. Materials with sulfur, sulfide

C. Materials with amine

Package

10kg/set (Part A 5kg + Part B 5kg)

40kg/set (Part A 20kg + Part B 20kg)

Shelf Life and Transportation

1. Twelve(12) months when stored at 25C in original unopened packages.

2. This is a non-dangerous product, it can be transported as general chemicals.

3. Products exceed the storage life should be confirmed normal before using.

Any questions of Addition Cure Encapsulant and Potting Compound for Thermal Conductivity HY-9055#, please feel free to contact Kaimi:

TEL: 086-755-89212369

FAX: 086-755-89948030

MOBILE:086-18938867528

Website: www(dot)szrl(dot)net

E-MAIL: hyju(at)szrl(dot)net

skype:hyjiangying

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents