Liquid Silicone Rubber(LSR) For Injection Molding

- US $16.36

200 - 40,000 kilogram

- US $9.86

40,001 - 999,999 kilogram

group nameinjection moulding silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY922# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 21:44:27 GMT

Paramtents

properties light viscosity

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

Liquid Silicone Rubber(LSR) For Injection Molding Description

liquid silicone rubber(LSR) for Injection molding is a two-part high purity addition cured silicone pecifically designed for liquid injection molding, which can be fully automatically injection molded without secondary processing.They are platinum curing and vulcanize under heat and pressure.

Liquid Silicone Rubber(LSR) For Injection Molding Applications

Injection molding of LSR are particularly suitable for products that require high precision such as seals, sealing membranes, diving devices,electric connectors, multi-pin connectors, infant products where smooth surfaces are desired, such as bottle nipples, medical applications as well as kitchen goods such as baking pans, spatulas, etc.

Liquid Silicone Rubber(LSR) For Injection Molding Advantages

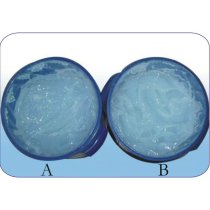

1, The elastomer is supplied as a two-part kit (Part A and Part B), equal portions (1:1by weight) of which is very easy to operate and ideal for manufacturing parts in large volumes, achieving low unit costs but super qulitied prouduct.

2,With low compression set, great stability and ability to resist extreme temperatures of heat and cold.

3, Excellent tear strength(≥35KN/m) ,High transparency,Almost non shrinkage, Good resilience,Anti-yellowing

4, Good heat stability and weatherability ( temperature resistant range of -60°C--250°C)

5, Comply with USA CFR21.Part.177.2600 and Chapter 4.9 Test Standards for Volatile Compound of EN14350-2 and EU RoHS Standard

Main products introduction

1, General Purpose Injection Moulding Silicone Rubber

Standard Datasheet:

Item | HY-921 | HY-922 | HY-923 | HY-924 |

Appearance | Transparent | Transparent | Transparent | Transparent |

Viscosity (Pa.S) | 400 | 600 | 700 | 600 |

Mixing ratio | 1:1 | 1:1 | 1:1 | 1:1 |

Density (g/cm3) | 1.07 | 1.08 | 1.10 | 1.12 |

Hardness (A°) | 30 | 40 | 50 | 60 |

Elongation at break (%) | 400 | 550 | 450 | 380 |

Tear strength (KN/m) | 25 | 35 | 35 | 35 |

Curing condition | After Mixed A with B according to mixing ratio of 1:1, 150mm×150mm×2mm, mould will be formed in 7 minutes under temperature of 150°C | |||

Liquid Silicone Rubber(LSR) For Injection Molding Detailed Application

HY-92XA/B series injection molding liquid silicone rubber, which is an elastomer cured under high temperature.

They are mainly used for fabricatingComponents,medical devices and parts, cake mold,household products,Diving device, medical catheter,medical tube,adult Soother,iPad/iPhone Case, insulation ”O”rings etc.

Package:The general packages of HY-92XA/B series is in 20kg and 200kg per barrel.

Notice.

NO.1,After the component A and component B are mixed under the temperature of 20 °C, the effective operating time is 5 days in sealing status, The effective operating time will shorten in case of rising temperature.

NO.2,The viscocity ,hardness and appearance/color of above products can be adjusted according to customer’s specific requirements.

MOBILE:086-18938867591

QQ: 18938867591

Skype: judy.zhao723

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents