Liquid Silicone Rubber For Coating Textiles

- US $12.98

200 - 40,000 kilogram

- US $10.88

40,001 - 999,999 kilogram

group namesilicone rubber for textile coating& trademarks

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-T0330

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 22:19:03 GMT

Paramtents

Appearance Transparent

Hardness(shore A) 30±2

Mix ratio(A:B) 1:1

Viscosity(mPa.s) 60000~100000

Pot life(25℃) 12-24 hours

curing time(100-120℃) 10~20(mins)

Packging & Delivery

Min Order200 kilogram

Briefing

Wearproof, wash-resistant, high temperature resistant

Detailed

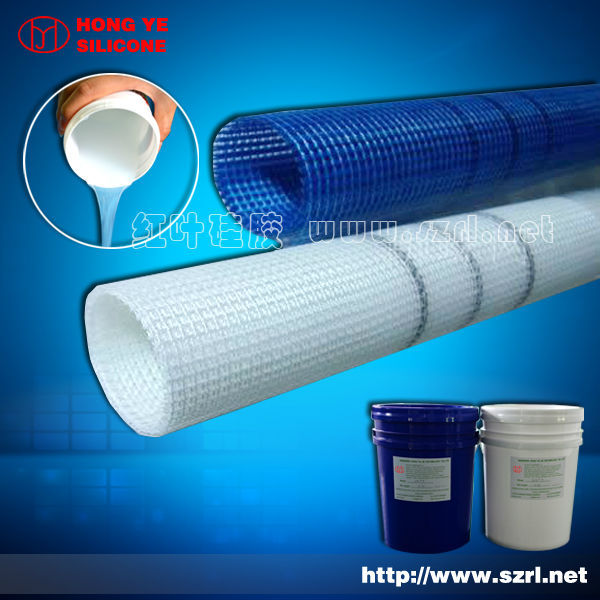

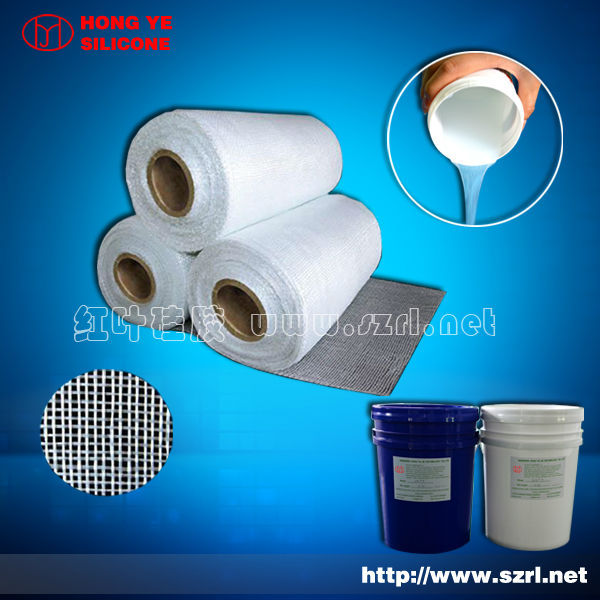

Liquid Silicone Rubber For Coating Textiles

About TB0330 Silicone Rubber For Coating Textiles,is a 2-part liquid silicone with high transparency, great tear-strength and strong bonding force. This product portfolio is complemented by water-based finished silicone rubber dispersions and a large number of special additives for customizing our standard grades. Textile coaters will thus find the perfect solution for every application at HY SILICONES.

TB0330 Silicone Rubber Application:

It is specially used for skid-proof purpose of frilals, underclothes and widely applied for cotton fabric, polyester-mixed cotton cloth, nylon cloth, flax, woolen, insulating cloth, etc.

Specification:

-Low shrinkage(<0.1%)

-Good skid-proof effect and high adhesive strength

-Wearproof, wash-resistant, high temperature resistant

-Non-toxic and odorless, food grade silicone

-High transparency and good tear-strength.

There is Datasheet show to you for referance:

Model | TB0330 |

Appearance | Transparent |

Hardness(shore A) | 30±2 |

Mix ratio(A:B) | 1:1 |

Viscosity(mPa.s) | 60000~100000 |

Tensile strength(Mpa) | 4.6 |

Tear-strength(KN/m) | 19±2 |

Elongation(%) | 360 |

Pot life/working time(25°C) | 12-24 hours |

curing time(100-120°C) | 10~20(mins) |

Operation introduction:

1,Mix Part A and Part B as ratio 1:1, you may add additive such as pigment as ratio 1~2% into part A.

2,It can be cured by heating with 100~150 degree, the curing time will be 5~10 minutes.

SHELF LIFE:

8-10 months when stored under 24°C in original unopened packages.

PACKAGE:

If ratio is 1:1 :Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

If ratio is 10:1 :Packed in 20kg/pail + 2kg/pail and 200kg/pail + 20kg/pail.

If need it,just call me :

Ms Samina:

mobil:86-18938867533

phone:86-0755-89212365

welcome to visit www(dot)szrl(dot)net

facebook :https://..........com/rtvsilicon

youtube :http://..........com/channel/UCed_-QO7UZneNYsWTxR1KFA

linkedin :http://..........com/profile/viewid=189510785&trk=nav_responsive_tab_profile_pic

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents