Liquid RTV Pad Printing SIlicone For Printing Machine

- US $9.88

200 - 40,000 kilogram

- US $6.00

40,001 - 999,999 kilogram

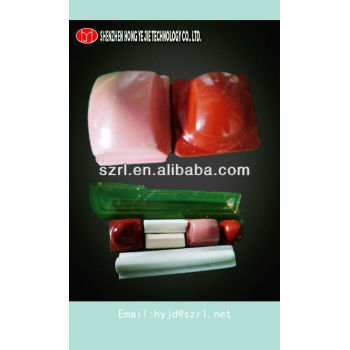

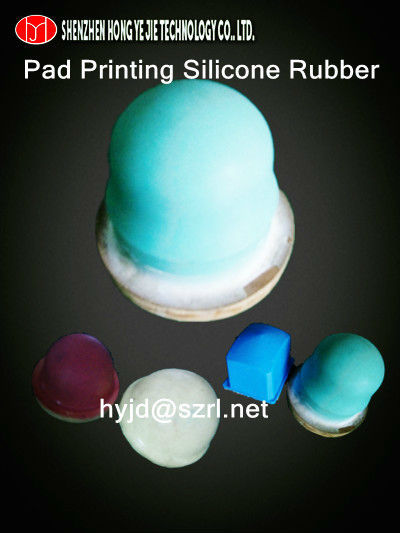

group namePad printing silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-9 for Printing silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeSat, 09 Nov 2013 11:50:33 GMT

Paramtents

COLOR White(different colors are available if requested)

NAME Silicone Rubber For Making Silicone Pad

PURITY 100%

DEMOULD TIME 2-4H

PRICE FOB shenzhen USD 5.8~8.5

QA/QC In House

Curing agent 5% for free charged

Hs Code 39100000

Packging & Delivery

Min Order200 kilogram

Briefing

2.good tensin and high tear strength

3.without impurity

Detailed

Liquid RTV Pad Printing SIlicone For Printing Machine

Liquid RTV Pad Printing SIlicone For Printing Machine description :

pad printing silicone rubber is specially designed for silicon pads which requires to be exquisite, without impurity or granules.

Silicon pad is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface.

Liquid RTV Pad Printing SIlicone For Printing Machine application:

pad printing silicone rubber is mainly used for printing irregular patterns of plastic toys, electroplating products, electronic toys, trademarks.

Liquid RTV Pad Printing SIlicone For Printing Machine advantages

pad printing silicone rubber with the advantages of abrasion resistance, high temperature resistance, and good in printing effect due to adding American Dupont Teflon high-temperature resistance new material. Applications: which made of top-quality raw material due to adding American Dupont Teflon high-temperature resistance new material, is processed through high-temperature machining.

How to use pad printing silicone rubber to make print pads

1. Firstly,clean the mold with detergent, and dry up the mold by a piece of cloth or an air gun and then coat the mold with a layer of release agent.

2. The normal proportion between the pad printing silicon and the silicone oil depends on the requirements of the customers.

3.General mixing proportion is as follows: add 30g silicone oil into 100g silicon with the hardness of the silicon pad being 20A°, which is suitable for the pad printing for alloy car and products with small patterns and contact areas.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents