pad printing silicone

- US $13.80

200 - 40,000 kilogram

- US $8.80

40,001 - 999,999 kilogram

group namePad printing silicone rubber

-

Min Order200 kilogram

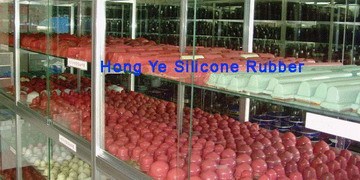

brand nameHong Ye silicone rubber

modelHY912

payment methodT/T, L/C, Westem Union

-

update timeSat, 09 Nov 2013 11:53:54 GMT

Paramtents

color red and green

sample available

HS code 39100000

catalyst free

package 25kg/drum or 200kg/drum

shelf life 1 year

Shipping Terms by sea/ Air lift

Certifications RoHS. MSDS. SGS. ISO.9001:2000

Appearance liquid

Payment Terms L/C at sight, T/T, West Union

Packging & Delivery

Min Order200 kilogram

Briefing

resistance to deformation

high-temperature

high printing times

good aging resistance

Detailed

pad printing silicone

Key words: pad printing silicone rubber, rtv silicone, pad printing silicone, liquid silicone for pad printing, silicone for pad printing, liquid silicone for printing.

Brief description of pad printing silicone

pad printing silicone as a carrier which transfer patterns on the steel plate to the toys products surface.

Applications of pad printing silicone

pad printing silicone is mainly applicable to the printing of irregular patterns on plastics toys, electroplating products, electronic toys, trademarks, artwork gifts, and stationery, etc.

Operation Instruction:

pad printing silicone is two-component silicone, part A is liquid silicon rubber, part B is catalyst. The usual mixture of silicone rubber and catalyst is 100: 2 or 100: 3. E.g. we take 100g of liquid silicon rubber and 2g-3g catalyst, mix them and pour it to your mold. A fter 2-4 hours, you will get a Pad printing silicone rubber.

1) At first, prepare all the tools like the pad mold, a cup for mixing, and a glass stick. Clean the pad mould with detergent, and dry the pad mould with an air-gun or cloth, then brush a lay of mold release agent.

2) For second step, adjust the ratio between the silicon rubber and silicon oil according the customer’s requirement. If customers want to print large pattern, soft silicon pad need and silicon oil need to add, otherwise, hard silicone pad need, less silicone oil to add or none.

Any questions for pad printing silicone , pls feel free to contact Ferry:

Mob: +86-13726807813

Tel: + 86-755-89948019

E-mail: hysd(at)szrl(dot)net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents