Liquid silicone for plaster mould making

- US $8.25

200 - 40,000 kilogram

- US $6.20

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelmolding silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeSat, 09 Nov 2013 12:47:27 GMT

Paramtents

Certification: SGS,MSDS,RoHS

HARDNESS: 18-40A

Mixing Ratio: 2%

Type: silicone rubber

Appearance: Fluid

Application: Mold making materials

EINECS No: 39100000

Purity: 100%

Curing agent: 5%for free charged

Packging & Delivery

Min Order200 kilogram

Briefing

2.for building decration

3 for artwork craft

4 for statues

Detailed

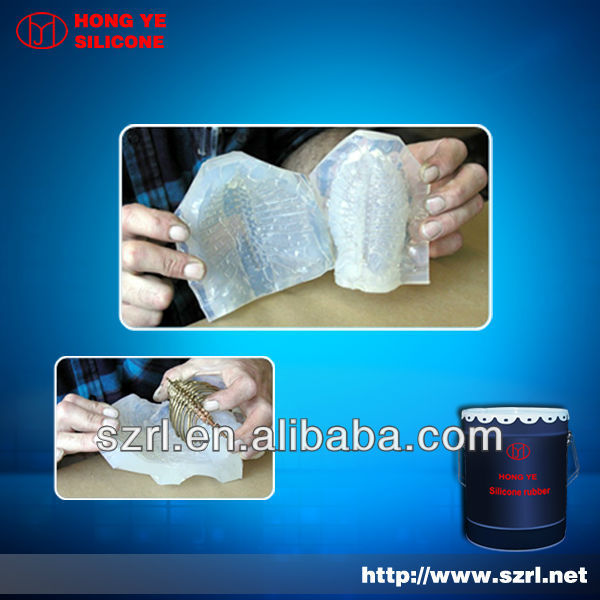

1. Application:

Liquid Silicone Rubber is primarily intended for poly resin crafts, PU crafts, PU resin crafts, gypsum crafts, unsaturated resin crafts, lighting and candles crafts, plastic toy, stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

2. Instruction:

Add curing agent of 2%-3% at the room temperature, the silicone rubber is still operational within 30 minutes, and in 2-3 hours.

1. Adding curing agent 1%, the silicone rubber can still be operated within 2.5 hours and can be Demoulded after 6-8 hours.

2. Adding curing agent 2%, the silicone rubber can still be operated within 50 minutes to 1 hour and can Be demoulded after 2-3 hours.

3. Adding curing agent 3%, the silicone rubber can still be operated within 28 - 30 minutes and can bedemoulded after 1.5-2 hours.

4. Adding curing agent 4%, the silicone rubber can still be operated within 10 - 15 minutes and can be demoulded after 1 -1.5 hours.

3.Standand datasheet :

Model | Color | Mixing ratio (%) | Pot life (mins) | Demould time ( hrs) | Hardness ( A0 ) | Tensile-strength (kgf/cm2) | Tear-strength (kgf/cm) | Viscosity (cps) | Shrinkage rate (%) | Elongation (%) |

638# | white | 100 : 3 | 30 | 5-10 | 38 | ≥ 38 | ≥ 28 | 34000-36000 | ≤0.3% | 380% |

630# | white | 100 : 3 | 30 | 5-10 | 30 | ≥ 47 | ≥ 35 | 28000 | ≤0.3% | 430 |

4.Steps:

Step One: Take 100g of part A and add 2g of part B and mix the silicone rubber and curing agent evenly.

Notes: Moulding silicon rubber is a kind of flowing liquid and it contains two parts. Part A is a kind of white flowing liquid and part B is the curing agent.

Step Two: vacuum pumping

Without exception, this step takes less than 10 minutes.

Note: The time for vacuum-pumping should be less than 3—5 mins , otherwise, once the silicone rubber has cross-link reaction during vacuumizing, it will not be operated.

Step Three: Brushing cast & Perfusion Molding operation

Any questions, please feel free to contact Mr Lucas:

TEL: 086-755-89212369

FAX: 086-755-89948030

MOBILE:086-18898736056

E-mail: hysj(at)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents