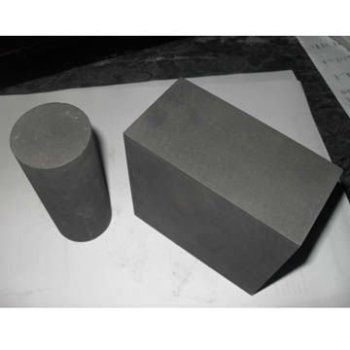

sintering graphite mould for diamond tools use

group namegraphite mould

-

Min Order1 metric ton

brand namewuzhou

payment methodL/C, T/T

-

update timeMon, 24 Jun 2013 00:33:42 GMT

Paramtents

rod size dia 700-1600mm, width 400-600mm

Chemical Composition synthetic graphite

block size dia 350x350 mm, 400x400, 450x450 mm, 500x500mm

Dimensions as customer's requirement

length 1800mm, 2100mm

Application machining diamond cutter head of diamond saw blade, diamond milling an

Packging & Delivery

Min Order1 metric ton

Briefing

2 Perfect material for sintering graphite mould,block of diamond tools.

Detailed

1.High purity, High density, and High strength

2 Perfect material for sintering graphite mould,block of diamond tools.

sintering graphite mould , block for diamond tool & plate & rod & tube & bar & round bar & round & sheet & anode bar

Introduction : Graphite sintering mould is used for machining diamond cutter head of diamond saw blade, diamond milling annulus, diamond aiguille, etc. It adopts graphite materials for hot-pressing and sintering of diamond cutter head. As the graphite has property of heat-resistance, oxidation resistance, hard mechanical intensity. We can machine various types and process according to designs.

1.ISO graphite

2. vibration moulded graphite block

3. Further processing graphite block

4. Dimensions are available on request

5. Specification

graphite block size: dia 350x350 mm, 400x400, 450x450 mm, 500x500mm

length: 1800mm,2100mm

graphite rod size: dia 700-1600mm, width 400-600mm

6. Technical Index

Bulk density (g/m3) | Max grain size (mm) | Ash (%) | Electrical Resistivity (μ Ω m) | Compressive Strength (MPa) |

1.60 | 0.8-2 | ≤0.5 | ≤10 | ≥20 |

1.68 | ≤8 | ≥22 | ||

1.72 | ≤7.5 | ≥25 | ||

1.75 | ≤7 | ≥28 |

7. Molded, Isostatic,Extruded,Vibrating,Impregnated

Further processing graphite, such as Impregnated graphite, Oxidation resistant graphite, etc.

8. Product advantage :

High thermal and chemical resistance,long service life,

competitive price , steady supply ability

9.Introduction:

Supply a wide range of High Purity Graphite blocks & rods & plates & sheets of different specification

Fine Grain Graphite Blocks & Rods & Plate are vibro-compacted and available in various sizes and grades. It is manufactured by fine grain petroleum coke. Its grain size, depending on different production processes, deeply affects the performance.

10. Application :

Graphite Blocks / Plates / Rods/Sheets /Bars are variously used in many productions and applications, such as Mold , Batteries, Electric Motor Brushes, Alternator Brushes, Burner usage, Metallurgy, Semiconductor Manufacture, Aviatic application, Chemicals, Energy, Nuclear and Glass Industry etc.

Others:Hard Alloys, Graphite Mold, Diamond Aiguille, Saw Sinter Film, semiconductor Monocrystal Graphite Mold, Continuous Casting, Casting Steel, Alloys casting, Metals Casting, Graphite for Ray-cable, Graphite for Mid or Mini-type Rocket, Crucibles.