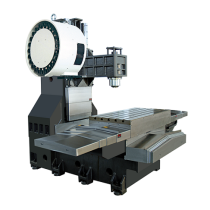

VMC1265 Vertical machining center

group nameVERTICAL MACHINING CENTER

-

Min Order1 piece

brand nameSINO CNC MACHINERY

modelVMC1265

payment methodL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

update timeMon, 26 Nov 2018 15:49:07 GMT

Paramtents

Control system FANUC, GSK, SIEMENS, MITSUBISHI

Packging & Delivery

Size330cm x 270cm x 300cm

Weight9000kg / piece

Min Order1 piece

Briefing

Detailed

Machine Characteristics

1.The major machine components apply finest gray cast iron which are of good shock resistance. All the casts have been done with aging treatment twice, in order to eliminate the internal residual stresses. So that, our machine can work with high rigidity and good

2.Key components are designed with CAD software, in this way, the optimal structure can be analyzed out by computer, which ensure the good intensity,rigidity and thermal

contacting area.

Machine Parameter

CODE | ITEM | DETAILS | ||

1 | Equipment | Vertical Machining Center | ||

2 | Factory | Sino Machinery Co.,Ltd | ||

3 | Model | VMC1265 | ||

Specifications | ||||

4 | Table size(L×W) | 1400×650mm | ||

5 | MAX.LOAD BEARING OF WORKTABLE | 1000 kg | ||

6 | Travel:X | 1200mm | ||

7 | Y | 650mm | ||

8 | Z | 665mm | ||

9 | Geometric accuracy | JB/T8771.2-1998 | ||

10 | Location accuracy standard | JB/T8771.4-1998 | ||

11 | PositionaI accuracy | ±0.012mm | ||

12 | Repositioning resolution | ±0.008mm | ||

13 | Control axes(X、Y、Z) | 3 axis | ||

14 | Spindle motor power | 11Kw/15 Kw | ||

15 | Spindle taper | BT50 | ||

16 | Max.Spindle speed | 6000 rpm | ||

17 | Drive type(Spindle) | Belt type | ||

18 | Distance from spindle nose to worktable mm | 115-780mm | ||

19 | Distance from spindle center to colum mm | 700mm | ||

20 | Fast feed(X/Y/Z axis) | 15/15/12/min | ||

21 | CUTTING FEED SPEED (X/Y/Z axis) | 0-6000mm/min | ||

22 | Drive type(X/Y/Z axis) | Servo | ||

23 | Guide way | Box type | ||

24 | Machine power | 20KVA | ||

25 | Protective cover | overall | ||

26 | Spindle parts balance | Dynamic balance G1 | ||

27 | T slots(No.×Width×Pitch) | 5×18×125 | ||

28 | Coolant flow rate | 40L/min | ||

Equipment work condition | ||||

29 | air compression | 0.5-0.7Mpa | ||

30 | Power request | AC380V±10% 50HZ | ||

31 | Temperature request | 5℃~+40℃ | ||

32 | Working Humidity | 20~80% | ||

33 | Dimension(L×W×H)mm | 3300×2700×3000mm | ||

34 | Machine weight | 9000 Kg | ||

35 | Machine spray | Standard | ||

Motor | ||||

Spindle motor | Model | βiI 12/ 10000 | ||

Max.speed | 6000 r/min | |||

Rated power | 11 KW | |||

30 mins overload | 15 KW | |||

Rated output torque | 52.5 Nm | |||

Feed motor | X/ Y | Model | βiS C 22/ 2000 | |

Max.speed | 2000 r/min | |||

Rated power | 2.5 KW | |||

Rated output torque | 20 Nm | |||

Z | Model | βiS C 22B/ 2000 | ||

Max.speed | 2000 r/min | |||

Rated power | 2.5 KW | |||

Rated output torque | 20 Nm | |||

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right