Household bottle mould blow bottle mould/blowing mould maker

- US $10000.00

1 - 100 set

- US $9900.00

101 - 200 set

- US $9800.00

201 - 300 set

- US $9700.00

301 - 400 set

- US $9600.00

401 - 500 set

group nameall

-

Min Order1 set

brand nameBeautyforever

modelBF-104

payment methodL/C, D/P

-

update timeMon, 12 Jun 2017 15:00:10 GMT

Paramtents

Place of Origin Guangdong, China (Mainland)

Brand Name Beautyforever

Style Household bottle mould

Design Custom

Certification ISO9001:2008

Runner Hot runner

Plastic mould 10 Years experience

Surface treatment Polishing

Package Standard export wooden case

Delivery 25-30Days

Packging & Delivery

Size60cm x 50cm x 45cm

Weight50.00kg / set

Min Order1 set

Briefing

Smooth surface, clear text patterns;

Detailed

Product description

1. Lowest cost, light and easy to release, less labor, economical;

2. Smooth surface, clear text patterns;

3. Beautiful and practical, no internal defect, simple operation;

4. Equipped with moulds and vibration table;

5. Has good toughness for using unique technology.

Name |

|

Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) |

Tolerance | ±0.2mm |

Processing | CNC, EDM,Wire cut, Milling, Griding, Drilling, Engraving, etc |

Mould base | Standard mould base,LKM, HASCO,DME,ect. |

Cavity | Depends on customer's requirements. |

Runner | Hot/cold |

Injection system | Motor/hydraulic cylinder/stripping plate/angle pin,etc |

Cooling system | In core baffle and in cavity plate chain drilling type cooling |

Design software | UG, PROE, CAD, CAXA, Solidworks ect. |

Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect. |

Surface treatment | Polish,high gloss,texture,sandblasting,chrome |

Mould life | 100,000-5,000,000 shots |

Delivery time | 15-45days |

Pacakge | Standard export wooden case |

Specification | Depends on customer's requirements. |

Our service:

1 Mould design,Mould making,Mould testing

2 Rapid Prototyping service

ABS Prototype

Injection mould

3D Printing Service

3.Plastic Parts Manufacturing, Products assembly and packing,Shipping

4. In-time response on letters, telephone calls or fax

5. In-time mould delivery.

Advantage:

- We are manufacture for nearly 10years

- Offer service all stages of the projects,from initial concept,mould design,prototype making,trials,mass production and inspection

- ISO9001:2008 and quality control team

- Low MOQ: It can meet your promotional business very well.

- OEM/ODM welcomed,

- Up-To-Date Software

- We will reply your inquiry in 12 hours

- Fast & Cheap Delivery: We have big discount from forwarder (Long Contract).

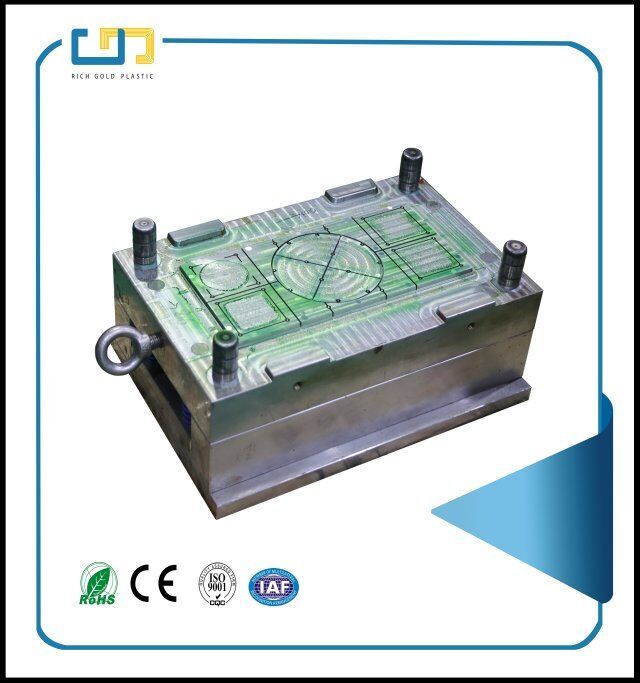

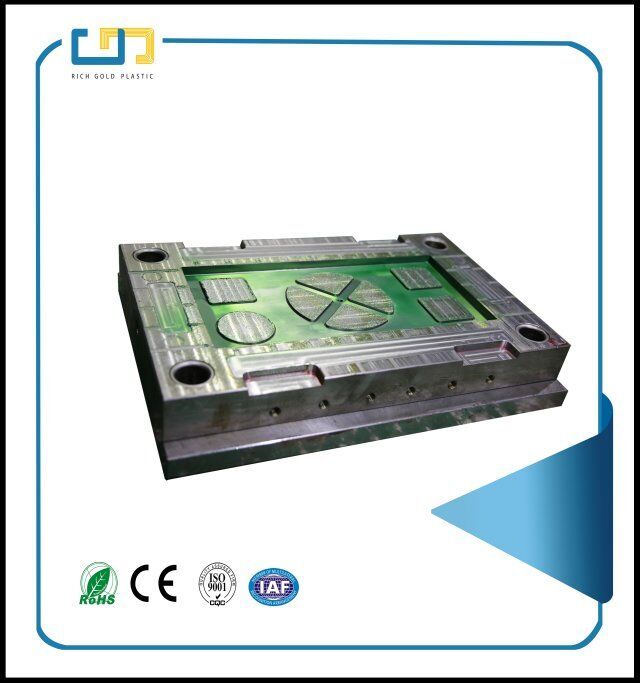

Detail images:

Main Operation Steps

1,Receiving information from customers(concept,sample,physical model,2D or 3D data)

2,Transforming the information into 3D data model by means of CAD system

3,Purchase the meterial

4,CNC Milling and EDM manufacturing

5,Mould-Trial and few samples produced

6,Delive the sample and get customers' opinion

7,Mould's final treatment

8,Deliver Moulds and provide customer services

1.Sample/Drawing | We need your detail require like as 3D&2D drawing and sample. We also can make the design if customer need |

2.Negotiation | Talk about the material, cavity, price, delivery time, payment term ,and etc. |

3.Place order | According customer’s design or choosing our design. |

4.Mold design | We will communicate and exchange the opinion with you during making drawing. |

5.Tooling mold | Start making the mould after customer approves the mould design. |

6.Mold process | Regularly provide tooling process. |

7.Sample confirm | Send customer samples for confirmation, if not satisfied, We will modify the plastic mould until meet customers satisfactory. |

8.Mass Production | After everything is ok, customer approved and signed the sample to us go ahead mass production |

9.Package | PE bag for production, wooden case for mould |

10.Delivery | Arrange shipment by sea or by air that according to customers’requirement. |

Related products

Company Information

Welcome to Dongguan Yuzimei Commodity Technology Co.,Ltd | |

Company history | Dongguan Rich Gold Industry Co.,is a plastic injection mould company.Built in 2007,factory covering more than 2000 square meters, and obtained ISO 9001:2008 Certificate. |

Main products | Manufacturing, supply and exporting custom injection molded products and plastic mould making |

Service | Offer service all stages of the projects, from initial concept, mould design, prototype making, trials, mass production and inspection |

Staffs | 50-100 employees |

Machines | Advanced CNC machining centers, EDM machines, wire cutting machines, high precision injection machines, grinding machines, fitting machines and full sets of engineering inspection machines |

Quality control | 6 members of Q&C Department, from material incoming, production, assembling to finished products |

Standard | According to CE, FDA, SGS, REACH, ROSH, etc |

Sales Market | Europe, North America, South-east Asian, South Africa, Middle East, China,etc. |

Certificates

Packing&Shipping

FAQ

1Q. I have an idea for a new product, but don’t know if it can be manufactured . Can you help ?

A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials tooling and likely set-up costs

2Q What are the advantages to having my parts manufactured locally?

A. Vertex can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand.

3Q. My components have already been developed on CAD. Can you use the drawings?

A .Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, model and mould tools this can save time and money in producing your parts.

4Q .Can I test my idea/component before committing to mould tool manufacture?

A .Yes, we can make CAD drawings to make models for design and functional evaluations.

5Q. What type of plastic is best for my design/component?

A. Material selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternative and suggest the best material.

Contact us

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- FOB, CIF, EXW, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Escrow