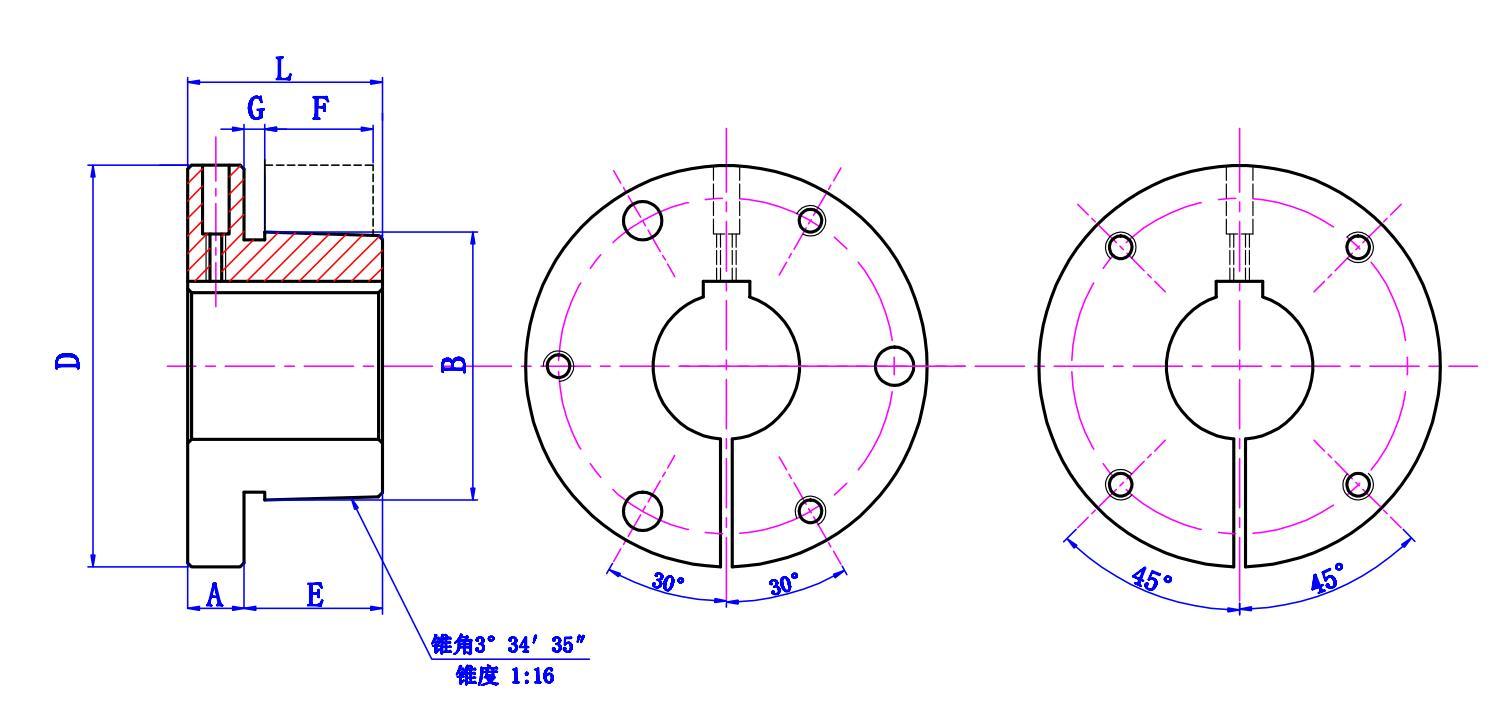

Martin Catalog QD Bushing JA

group nameQD Bushings

-

Min Order20 piece

modelMartin Catalog QD Bushing JA 1-1/4"

payment methodL/C, D/P, Western Union

-

update timeThu, 06 Jun 2019 17:35:02 GMT

Paramtents

Product QD Bushing JA

Material steel C45

Catalog Martin

Surface Treatment Blackoxided

Packging & Delivery

Weight0.85kg / piece

Min Order20 piece

Briefing

Detailed

Bushing Name: | JA |

Weight: |

0.90Lbs |

Material: | Steel |

Bore: |

finished |

A: | 0.375" |

B: |

1.375" |

D | 2.000" |

E: |

0.688" |

F: | 0.563" |

G: |

0.125" |

L: | 1.000" |

Keyway |

Yes |

SetScrews: | 10-24 |

CapScrews |

3-10x1 |

Contact: Jimmy

Mail: info..........com/jimmy..........com

what app:+86 13588027172

Mobil: +86 13588027172

wechat:zjsprocket

Facebook: smartbhz..........com