Steel Casting Parts For Customized Metal Products, Stell Casting From China

group nameShell Mold Casting

-

Min Order200 piece

brand nameFC Precision Casting & Investment Casting

modelShell Mold Casting-5

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeTue, 19 Dec 2017 13:48:13 GMT

Paramtents

Brand Name Fuchun

Application Engineering Machinery Parts

Dimensions Customized

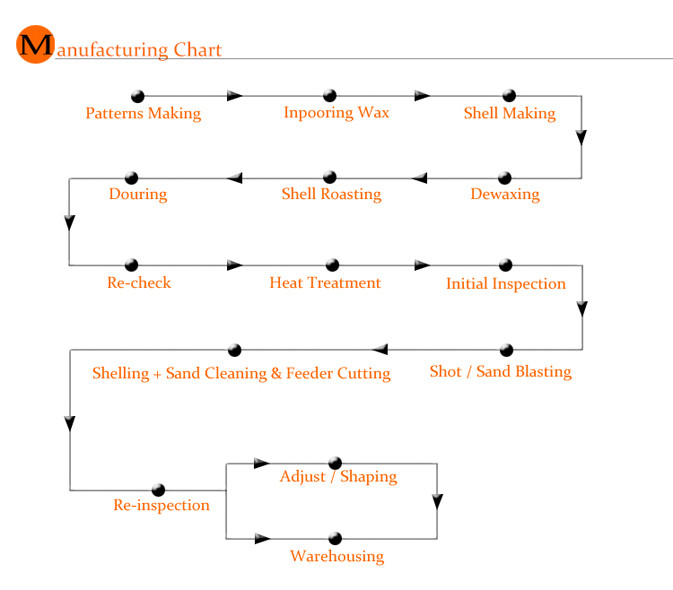

Process Precision Casting

Material Steel, Iron, Steel, Gray Iron,Nodular Cast Iron

Surface Machining Or Spay Painting

Inspection Pressure Test, Sealing Test

Heat Treatment Annealing, Normalizing, Quenching, Tempering

Production Equipments Advanced

Technology Strength Powerful Technology Team

Packging & Delivery

Size120cm x 80cm x 55cm

Min Order200 piece

Briefing

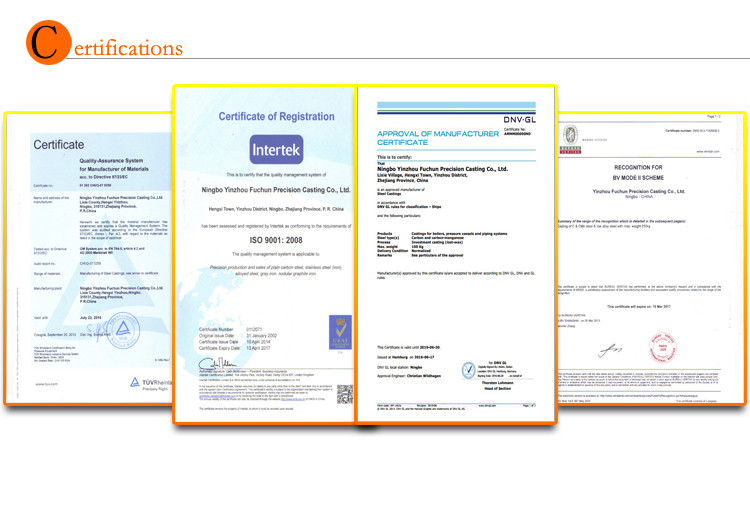

Approvals ISO9001, SGS,TUV,BV,DNV,GL

Detailed

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd. was set up in 1988, located in the beautiful coastal city of Ningbo, on China's eastern seaboard.

One of the leading foundries in China, we specialize in casting of carbon steel, alloy steel, gray steel, stainless steel and ductile iron materials. With an annual output capacity of 10000 metric tons, our products range from 100 grams to 600 kilograms in weight.

We also produce mechanical parts for worldwide purchasers and can manufacture as per customers' drawings. Until now, our products can be mainly put into the following categories: valve parts, parts for rail and subways, parts for mining machinery, automobile fittings, parts for hydraulic machinery, parts for project machinery and other parts.

With 7 medium frequency electric furnaces for production, we also have spectrographs, metallographic analyzers, hardness testers, ultrasonic test machines, magnetic particle flaw detectors, impact testers, tension testers and other inspection instruments. Furthermore, our machining capability is very strong, with a whole line of boring, milling and drilling lathes, 13 CNC lathes, 4 CNC machining centers, and related metallurgical machinery.

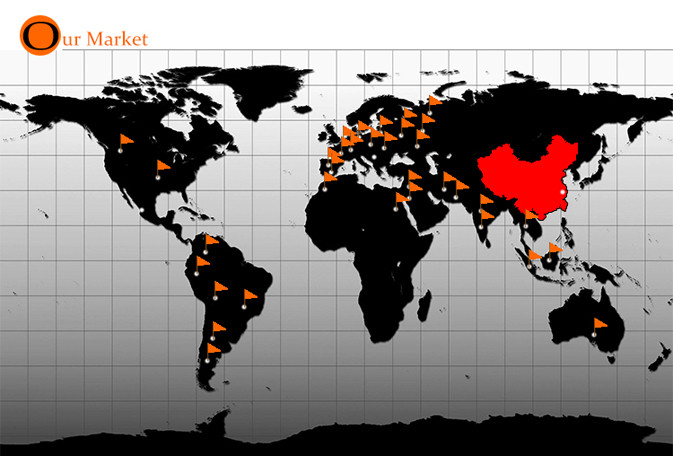

We put great emphasis on our quality control system to assure our products have the best quality. We have already passed ISO9001, TUV-PED and BV approvals. 80% of our products are exported to Europe, the USA, and Australia; where they are well received by customers, with whom we have established long term business relationships.

We believe that good quality and honesty help us win customers. We are looking forward to working with you and establishing mutually beneficial business relationships with you. If you are interested in our products, please feel free to contact us for more details

High quality testing machine: Metallographic Analyzer,Rally Machine

Precision Spectral Analysis Machine

Hardness Machine,Ultrasonic test Machine

Magnetic particle flaw detector

Imapact test machine

Projection measuring instrument

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai, Qingdao, Xiamen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal, Cash