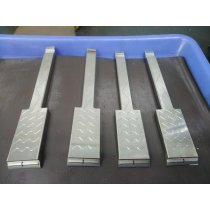

Customized Precision Mold parts for Auto Connector injection molds

group nameprecision mold parts

-

Min Order1 piece

modelKR001

payment method

-

update timeThu, 19 Apr 2018 14:22:55 GMT

Paramtents

Place of Origin: Dongguan, China (Mainland)

Minimum Order Quantity: 1 Pcs

Price: Negotiable

Packaging Details: Inner package with PE film first, then out package with Plastic box, carton last,Base on customer's requiry.

Delivery Time: Normally, simple parts, 5-7 days, complicated parts, 7-15 days. according to customer drawing, quantity and material,special case will be sooner

Payment Terms: T/T 50% as deposit 50% before shipment

Supply Ability: 1200-1500 units per month

Size: According To Your Drawing

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Customized Precision Mold parts for Auto Connector injection molds

Main Information

1. Material: Steel (D2, K40, G8, 1.2379, 638, 1.2316, S136H, etc. )

2.Material brand: DAIDO, SAARS TA, AISI, ASSAB, HTTACHI , etc.

3. Machining: grinding and EDM machining.

4. Applicated software: Pro/E, Auto CAD 2000,solid work 2001,CAXA,UG,CAD,CAM

5. Precision of grinding :0.001 mm

7. Precision of EDM: 0.002 mm

8. Surface roughness: Ra0.4 um

9. Verticallity: 0.002 mm

10. Mold parts application: auto connector

Inspection: Nikon Projector, Nikon 2.5 Dimesion, Nikon Height Gauge and so on. Packing: Anti-rust oil, PE film wrap each by each, then small plastic box. Delivery: Normally 7-15 days, depends on drawings. the express include DHL, Fedex, UPS... |

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- Express Delivery

- Acceptable payment methods

- T/T