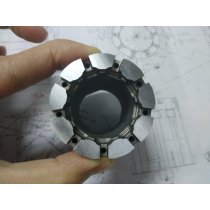

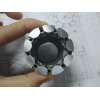

Square Stainless Steel Precision Mold Parts Surface Grinding Machining

The Part Introduction

1). Part Machining: For this product we see, it is only processed by grinding and discharging. But this does not mean that our mold parts processing will be limited, and we can also provide the following list of processing: CNC milling, internal- external lapping, wire cutting, abd more.

2). Material Available: The mold parts are made of stainless steel material. In our factory, the choice of materials is according to customer's drawings, so please don't worry, if you have the drawings need to be processed, you can be assured to send your drawings to Kingrui, we will provide the materials according to your requirements, and can show material proof.

3). Part Application: Since its establishment in 2005, after more than 11 years of efforts and development, our products have been applied in many fields, such as medical equipment, electronic equipment, aviation, electronic products (mobile phones, computers) and so on.

4). Machining Basis: Drawings or samples sent by customers.

5). Part Design Software: Pro/E, auto CAD, UG, CAD,PDF and more.

6). Inspection Instrument: Projector for digital measuring instrument, Japan Nikon Height Gages, Two dimension and so on.

7). Machining Equipment: The processing equipments involved here are Surface - grinding machines, EDM machines.

8). Part Tolerance: We are able to achieve high accuracy requirements of 0.001 mm.

Detail Description

Processing Range | CNC machining, Injection mold parts machining, wire cuting machining, precision grinding machining, EDM machining, internal- external lapping machining and so on. |

Material | Steel, aluminum, brass, stainless steel, high- speed steel,iron, zinc, etc. |

Specification | Based on customer's drawing or sample |

Finish | Polishing, mirror pilishing, DLC coating, PVD coating and so on. |

Tolerance | +/-0.01- 0.005 mm or according to your drawings |

File Format | Solidworks, Pro/ Engineer, Auto CAD, PDF, JPG and so on. |

| Equipment | CNC miling machine, surface- grinding machine, wire cutting machine , EDM machine, internal- external lapping machines, etc. |

Production Output | 1200- 1500 pieces per month, with high accuracy and difficulty. |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

Packing | PE film + Plastic bag +carton box or as customer's requirement to do |

Lead Time | Usually it takes 5- 15 working days If you have any urgent need, please let us know at any time. We will do our best to coordinate the production plan for you and ensure a pleasant cooperation. |

Payment Term | T/T, 50% as the down payment, the remaining 50% will be paid before shipment. |

Technic Series

- CNC machining

- Wirer cutting

- CNC milling

- Plane grinding

- Internal- external lapping

- Centerless grinder

- EDM processing

- Laser engraving

- And other processing can be available.

Packaging & Delivery

Packaging Details

1. With Antirust oil and PE film, the rust prevention during transport.

2. To be packed in plastic and cartons. Prevent vibration and slide.

3. Use glues tape to seal cartons.

4. Deliver out by DHL,FEDEX Or according to customers' requirement.

Delivery Time

Shipped in 5-15 working days after payment