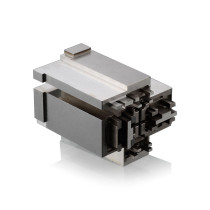

Precision Connector EDM Spare Parts Machining Services ISO9001 2008 Certification

Parts Introduction

1). Part Machining: For this EDM component, its processing techniques are mainly grinding and discharge machining. The above two processing is our best process in our factory, if your parts have this demand, we will give you satisfactory processing services.

2). Material Available: HPM7 is used there. Kingrui is a customized processing enterprise, in addition to product customization, materials can also be selected according to your requirements. There is nothing that can't be changed here, as long as it is convenient for our customers.

3). Part Application: This EDM component is used on injection molds as a type of computer connector.

4). Machining Basis: The processing of this mold part is based on the customer's drawings, so if you have the processing requirements, just send us 2D or 3D drawings

5). Part Design Software: Auto CAD, UG, CAD,PDF or others.

6). Inspection Steps:

- First, material inspection is to confirm the material that the customer needs.

- Second, product inspection during processing.

- Third final inspection of finished products.

- Fourth, submit our professional quality inspection report.

7). Machining and Inspection Equipment: Surface grinder and Sodick EDM machines; Projector, various height gages, two dimension, micrometer and so on.

8). Part Tolerance: We can reach 0.001 mm

OEM Manufacturer for EDM Spare Parts

- Materials: SKD11, DC53, PD613, SKH51, 1.2344, 1.2343, M2, M4, S7, etc

- Product weight: from 0.010 to 10kg/ pcs

- EDM spare parts for Over 11 years

- Software for drawing: pro/ E, auto CAD, UG, CAD,PDF and Solid works2008 flow analysis

- Further machining work: turning and wire cutting, milling, grinding, internal- external lapping processing and CNC milling, etc.

- Surface finish process: polishing shot blasting, chromate plating, power coated and anodizing,etc.

- OEM parts range: auto parts, electronic parts, medical parts and other industrial uses

- Processes: CAD service, metal processing, surface plating, quality testing, packaging and shipping.

- Made according to customer's drawings, specifications or sample

- Products shown on the website are OEM produced

- Machining capacity: 1200 to 1500 pcs/ month

Advantages

1. Professional manufacturer for precision mold parts, cnc machining parts, internal - external lapping machine parts, EDM processing parts, etc.

2. Over 11 years experience.

3. Surface treatment: smooth and beauty or according to client's request.

4. 100% inspection on critical dimensions with high accuracy +/-0.01- 0.005 mm

5. Factory direct price and on time delivery

6. Small quantity acceptable

7. OEM workable