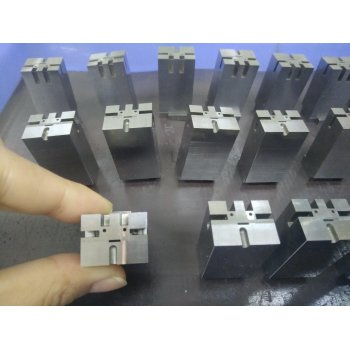

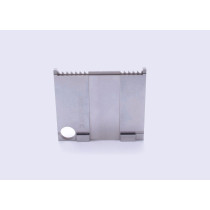

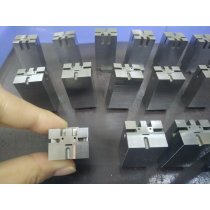

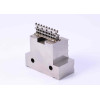

High Accuracy Wire EDM&EDM Sinker Machining Parts for Automotive Connector Molds

group namewire edm parts

-

Min Order1 piece

modelKR001

payment method

-

update timeTue, 15 May 2018 17:02:47 GMT

Paramtents

Place of Origin: Dongguan, China (Mainland)

Minimum Order Quantity: 1 Pcs

Price: Negotiable

Packaging Details: Inner package with PE film first, then out package with Plastic box, carton last,Base on customer's requiry.

Delivery Time: Normally, simple parts, 5-7 days, complicated parts, 7-15 days. according to customer drawing, quantity and material,special case will be sooner

Payment Terms: T/T 50% as deposit 50% before shipment

Supply Ability: 1200-1500 units per month

Size: According To Your Drawing

Packging & Delivery

Min Order1 piece

Briefing

Detailed

High Accuracy Wire EDM&EDM Sinker Machining Parts for Automotive Connector Molds

Descriptions:

| Product Name | High Accuracy Wire EDM&EDM Sinker Machining Parts for Automotive Connector Molds |

| Precision Machine | Precision grinder, Precision Wire Cutting, EDM Sinker& CNC, etc. |

| Applied Software | PRO/E, Auto CAD, UG |

| Material | The wire EDM parts is made of 1.2343. ready for per customer according to your demand. |

| Processing | For the these parts of display , their main processing technology is three steps: firstly grinding by the surface grinding machine, check this process without any problems after the next item, that is line cutting processing to ensure that all the process satisfied with customer drawings requirements, and then discharge processing. |

| Surface Finish | EDM Area according to VDI2400 16-18 or better |

| Dimension | As per customer's request. |

| Tolerence Precision | +/ -0.002- 0.005mm/ can also be customized |

| Lead time | Base on the quantity of order( usually 5- 15 working days) |

| Quality System | Full inspection beforie shipping |

| Packing | *Eco-friendly PE film / plastic box / carton box |

*As customer's specific requirements | |

| Shipping | By DHL, UPS, FEDEX& etc. |

| Near Port | Shenzhen and Guangzhou |

Our Facilities

Machining Facilities:

- FANUC CNC milliing machining 2x

- Mitsubishi mirror EDM 2X

- Sodick mirror EDM 2X

- Taiwan Qunji EDM 3X

- Surface-grinding machine 11X

- High-speed CNC engraving 2X

- Basic Milling 1x

Testing Facilities:

- NIKON Projectors 2x

- TRIMO Height Gages 2x

- Nikon Height Gages 6x

- Two dimension 1x

- Calipers 12x

- Rockwell 1x

Packing and Delivery

| Packaging Details | 1) PE film covered 2) plastic box then carton 3) as customized requirements. |

| Delivery Detail | Usually 5-15 days, it depends on the quantity of your order. |

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- Express Delivery

- Acceptable payment methods

- T/T