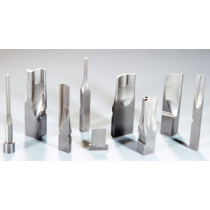

Normal Plus Mirror Parts Precision Complex Shaped Mold Cavity Inserts

group nameprecision mold parts

-

Min Order1 piece

modelKR087

payment method

-

update timeTue, 26 Jun 2018 16:13:00 GMT

Paramtents

Place of Origin: Dongguan, China (Mainland)

Minimum Order Quantity: 1 Pcs

Price: Negotiable

Packaging Details: Inner package with PE film first, then out package with Plastic box, carton last,Base on customer's requiry.

Delivery Time: Normally, simple parts, 5-7 days, complicated parts, 7-15 days. according to customer drawing, quantity and material,special case will be sooner

Payment Terms: T/T 50% as deposit 50% before shipment

Supply Ability: 1200-1500 units per month

Size: According To Your Drawing

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Normal Plus Mirror Parts Precision Complex Shaped Mold Cavity Inserts

Main Features:

| 1). Production mode : according to 2D/3D data or samples; | ||||||

| CAD/UG/ProE software we use | ||||||

| 2). Material:high-speed steel, special material can customize. improt material: SKD11,SKH9,SKH51, SKH51 | ||||||

| Material Brands: ASSAB/Daido/Hitachi... | ||||||

| 3). Technique standard : according to national standard GM, JIS,DIN,AISI ect, and other national standard to making | ||||||

| DIN and AISI are the normal standard | ||||||

| 4). Technique advantage : grinding parts with precision less than 0.002mm, precise EDM parts with precision less than 0.005mm | ||||||

| Mirror EDM Ra0.04 | ||||||

| 5). Utilization scope : precision punch mold, precision plastic mold, precision auto mold, precision medical mold, precision computer connector mold and other factory automation part etc. with many areas | ||||||

| Mainly Plastic automotive connector injection molds | ||||||

| 6). Production equipment : all machinery used from improt, with EDM ten sets. grinder 15 sets, wire-cutting, CNC, milling machinery. | ||||||

| 7). Product accuracy : diamension tolerance +-0.001mm, axiality within 0.002mm,roundness within 0.0015mm, surface roughness within Ra0.025, straightness within 0.002 | ||||||

| 8). Packaging type : Paper of Box | ||||||

| PEfilm with Anti-rust oil | ||||||

| 9)cooperation customer : China, Western, Japan, Southeast Asia |

90% in European Market

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou

- Delivery clauses under the trade mode

- Express Delivery

- Acceptable payment methods

- T/T