CNC Gantry Machining Center

group nameGantry Machining Center

-

Min Order1 piece

brand nameDRC

modelGMF4022

payment methodL/C, T/T

-

update timeTue, 07 Apr 2020 13:52:13 GMT

Paramtents

Worktable size 4000/1800mm

Max loading of worktable 12000KG

T-slot 9-22×200mm

Gantry width 2230mm

Travel for X/Y/Z axis 4200/2200/1000mm

Distance from spindle nose to table surface 310-1310mm

CNC system FANUC 0i-MF

Rapid shift of axes of X/Y/Z 10/12/10m/min

Standard tool quantity BT50/32

Positioning accuracy 0.021mm

Accuracy of repeated positioning 0.02mm

Motor power of spindle 22/26kw

Integrated weight 37000kg

Packging & Delivery

Min Order1 piece

Briefing

Detailed

What Is DRC Machinery's GMF series CNC Gantry Machining Center?

DRC Machinery’s GMF series Gantry Milling Machining Center is widely used in the aviation, auto, precision molding industries. GMC series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

What Is The Application Field of DRC Machinery's GMF series CNC Gantry Machining Center?

( More Detailed Picture of GMF series CNC Gantry Machining Center)

The production base of DRC Machinery is professional CNC Gantry Machining Center.

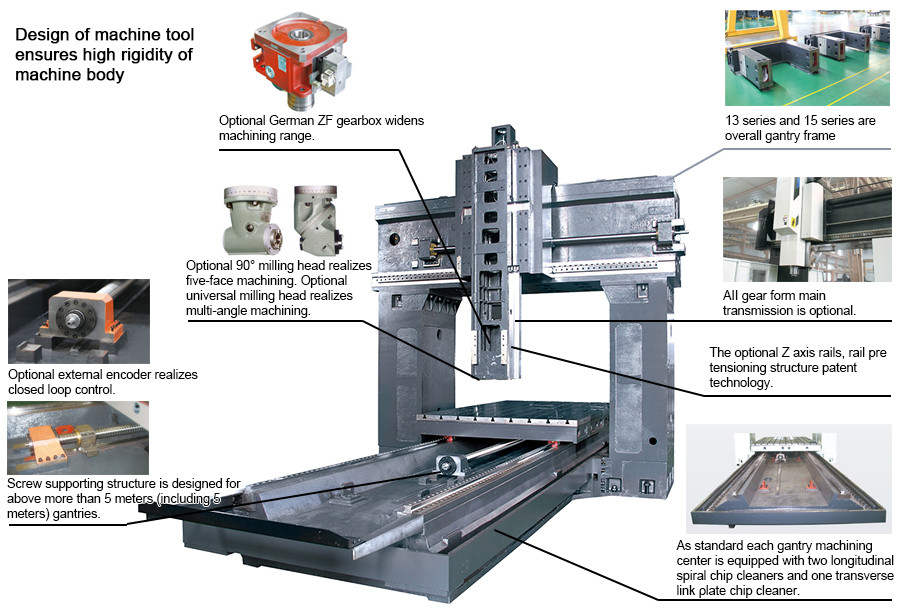

GMF series CNC Gantry Machining Center is designed of machine tool ensures high rigidity of machine body and has Strong spindle, ensure perfect processing.

What Is The Details Of DRC Machinery's GMF series CNC Gantry Machining Center?

1.Design of machine tool ensures high rigidity of machine body

The structure of machine tool is analyzed with ANSYS at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

2.Strong spindle, ensure perfect processing

The gear type spindle variable speed device provides powerful torque during operation at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.

Bed Body

The structure of the machine tool isanalyzed with ANSYS at all stages from foundation design to gurantee high speed and high precision continouos machining.A simulation testing for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

Spindle

The gear type spindle variable speed device provides powerful torque during peration at low speed and guarantees stable rotation during operating at high speed so as to enable wider machining range.

By enlarging diameter of spindle ends and flanges, the spindle with roller bearing could strengthens all factors related to spindle system.

ATC(Automatic Tool Changer)

Automatic tool changer is composed of tool maagazine and tool changing arms.Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasoons on precision. Tool selection adopts the method of fixed address in the shartest path.

Send Inquiry Here to Get a Free Work-piece Sample!

Company Introduction

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

◎CNC Lathe

◎Conventional Lathe,

◎Vertical Lathe

◎Machining Center

◎Boring and Milling Machine

◎Dental Milling Machine

◎Glass Tempering Furnace

◎Special Machine for Pipe Threading ,Valve Milling, End Facing and so on

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C