Heavy Duty Lathe Machine

group nameConventional Lathe

-

Min Order1 piece

brand nameDRC

modelCS61125

payment methodL/C, T/T

-

update timeThu, 19 Dec 2019 10:52:37 GMT

Paramtents

Certification: ISO9001

Dimension(L*W*H): 6650*2380*2040mm(min)

Packging & Delivery

Min Order1 piece

Briefing

Detailed

CS61125 Heavy Duty Kirloskar India Romania Pakistan Bench Lathe Machine For Stiansteel

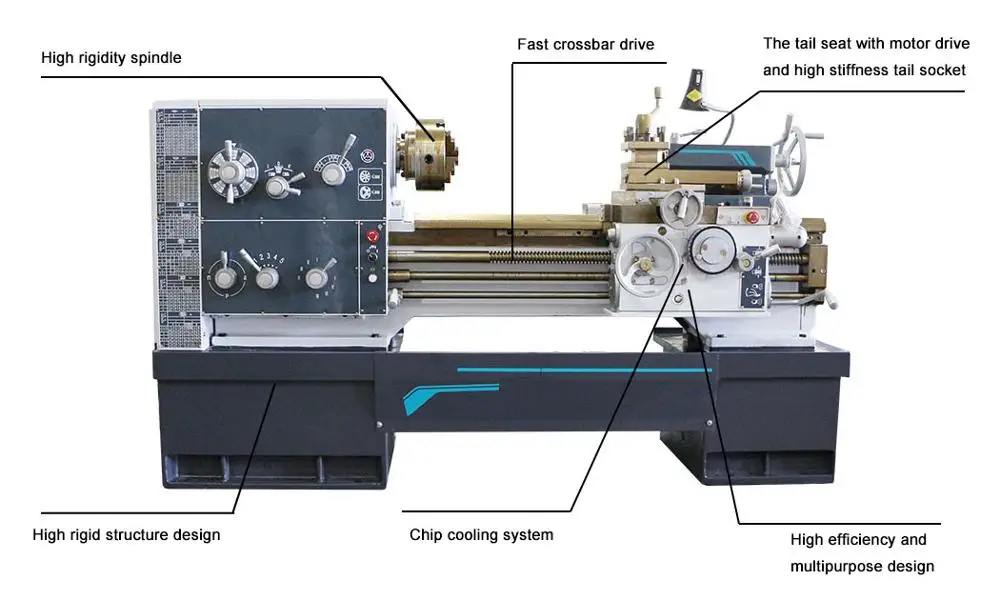

What Is DRC's CS series Conventional Lathe ?

CS series conventional lathes is mature, and this series lathes have the following characters, such as big power, rigidity, spindle speed range, apply force or speed cutting, can be completed on a variety of shaft and disc-type parts of the external cylindrical surface, conical surface , grooving, chamfering, drilling and tapping machining processes, and can processes metric thread, inch thread, modulus thread, thread pitch and taper thread, the knife can cut short cone vehicle longitudinal feed and feed on the turret motor complex exercise can cut the long cone, excellent for large complex parts and can show superiority.

What Is The Application Field of CS series Conventional Lathe?

( More Detailed Picture of CS series CNC Lathe Machine )

1.According to the different needs of the user configuration, there are metric, imperial, and other types of public bilingual.

2. Spindle box with mechanical friction disc clutch, without changing the motor speed and stop the motor can be realized spindle speed, stop, change direction.

3.machine apron with fast-moving device, with overload protection device; vertical and horizontal cross bar handle, opening and closing nut handle.

Without changing hanging round, you can turning metric, inch, module, thread pitch.

4. metric available tools, Inch machine, the left wheel apron and many other combinations;

5.Head stock with clutch

6. machine tool spindle head in the form of C6;

7. Headstock machine, feed box with oil pump lubrication;

8.Apron with rapid traverse control.

What Is The Details Of CS series Conventional Lathe?

This machine adopts the traditional horizontal lathe layout, the whole design, rigid, meets the safety standard. The main basic parts of bed and head of the bed are all cast in resin sand, the artificial aging treatment and the stability of the whole machine are superior. The bed body adopts HT300 material, the guide rail of the bed surface of the lathe is quenched by high frequency, the guide rail is G50, and the guide track life is improved.

2.High efficiency and multipurpose design

It can complete the external cylindrical surface of shaft and disc type parts, taper and grooving, chamfering, cutting drilling and tapping, and can process the commonly used metric thread, thread pitch modulus (special thread to consult), the knife frame can be cut short for motor vehicles the composite motion cone, vertical turret into the feed can cut a long cone of motor vehicle.

3.High rigidity spindle

The head stock machine control handle with centralized control, easy operation, the spindle system supported by three point, and the bearing of high precision, strong rigidity, brake axis and the positive and negative changes to the hydraulic control, sensitive and reliable braking, can transform a button to stop the speed, the bed head box with forced lubricating oil pressure, the head stock has beautiful appearance, good rigidity, high precision, stable operation, low noise, easy assembly, small deformation characteristics of spindle thermal.

4.Fast crossbar drive

The slide box of the machine is equipped with a fast moving device, which can quickly move to the desired position.

5.The tail seat with motor drive and high stiffness tail socket

The machine tool is equipped with the motor drive device, especially the larger length specification, which reduces the labor intensity and provides the working efficiency.

6.Chip cooling system

In order to ensure the clean of the site, there are dandruff plates in the lower part of the bed to ensure that the chip is removed from the processing zone. The independent cooling system is equipped with large flow cooling pumps to provide mandatory cooling for turning processing.

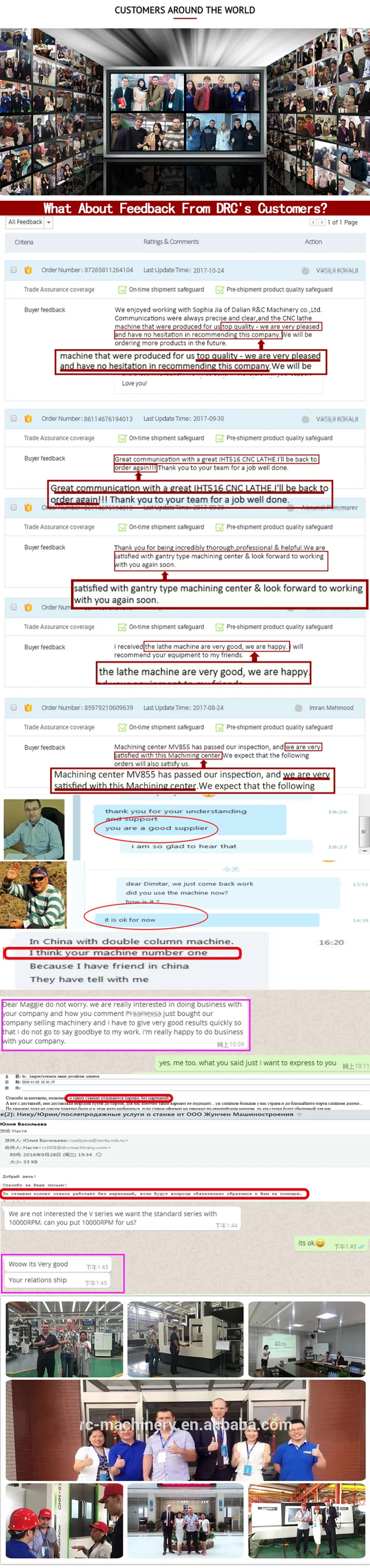

What Is The Historical Order Of DRC?

Below are some orders , click the photo to get more information.

Who Is DRC?

DRC is a group company ,which is professional in products and sales of advanced CNC machine tools . Acting full operation of the six machine tool production company's overseas sales.

DRC is located in Dalian, which is one of the largest seaport cities of China.Our products exported to Russia, Dubai, Hungary, Italy, Argentina, the Philippines, India, Iran, more than 50 countries.

DRC has six factories in China, which covers many kinds of mechanical equipment.

Product Range:

CNC Lathe

Conventional Lathe,

Vertical Lathe

Machining Center

Boring and Milling Machine

Laser Cutting Machine

Dental Milling Machine

Glass Tempering Furnace

Special Machine for Pipe Threading ,Valve Milling, End Facing Machine and so on

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C