Double Column Gantry Vertical Machining Center

group nameGantry Machining Center

-

Min Order1 piece

brand nameDRC

modelGMF 32 Seires

payment methodL/C, T/T

-

update timeThu, 27 Feb 2020 09:29:40 GMT

Paramtents

Power(W): 22kw

Machine Type: 3 axis heavy gantry machine controller

Precision: 0.021mm

Dimension(L*W*H): 7140*4200*4580

CNC system: FANUC 0i MF

Spindle specifications: BT50

Application: Molding Processing

Weight: 21000KG

Spindle speed: 6000 Rpm

Processing: Metal Cutting Cnc Milling Machine

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Structure

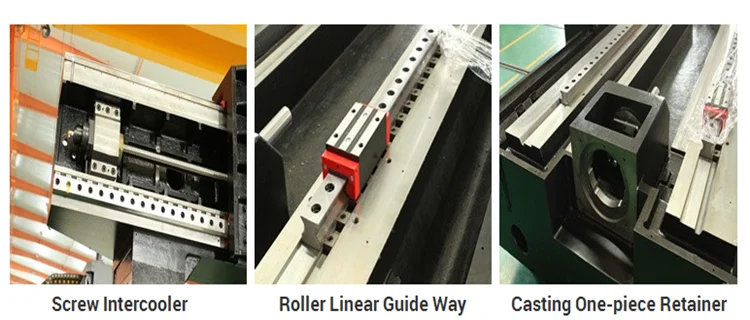

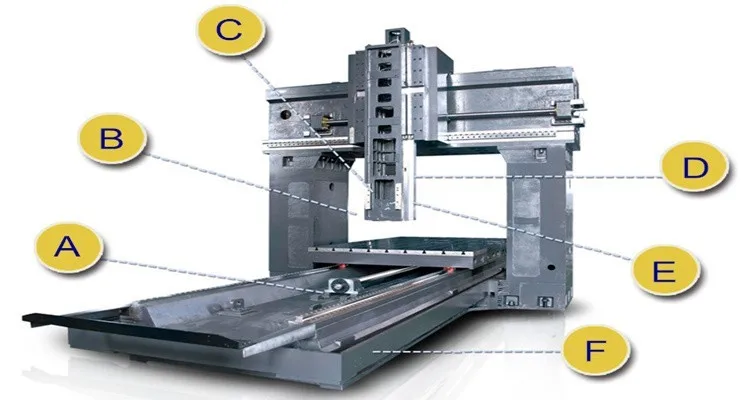

The structure of machine tool is analyzed with ANSYS at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

A1. Optional external encoder realizes closed loop control

A2. Screw supporting structure is designed for above more than 5 meters (including 5 meters) gantries.

D. Optional 90° milling head realizes five-face machining. Optional universal milling head realizes multi-angle machining

E. Optional German ZF gearbox widens machining range.

F. As standard each Guosheng gantry machining center is equipped with two spiral chip cleaners and one chain chip cleaner.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

GMC 32 Planer Type CNC Gantry Milling Machine With Customize

Widely used in the aviation, auto, precision molding industries. GMC series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C