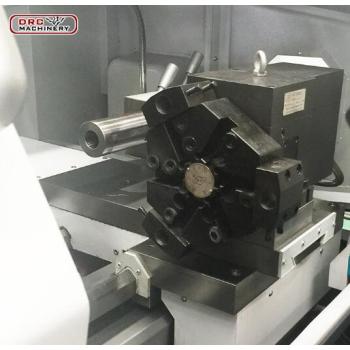

cnc lathe machine CKA61100A desktop cnc lathe

group nameCNC Lathe

-

Min Order1 piece

brand nameDRC

modelCKE61100A

payment methodL/C, T/T

-

update timeThu, 14 Nov 2019 13:36:24 GMT

Paramtents

Power(W): 50Hz

Certification: ISO9001&CE

Control system: GSK SIEMENS FANUC

Spindle speed: 150-2500rpm

Max. Swing Diameter: 1000mm

Dimension(L*W*H): 3455*2020*2000

Voltage: 380V

Weight: 1500kg

Machine Type: flat bed cnc lathe

Spindle bore: 110mm

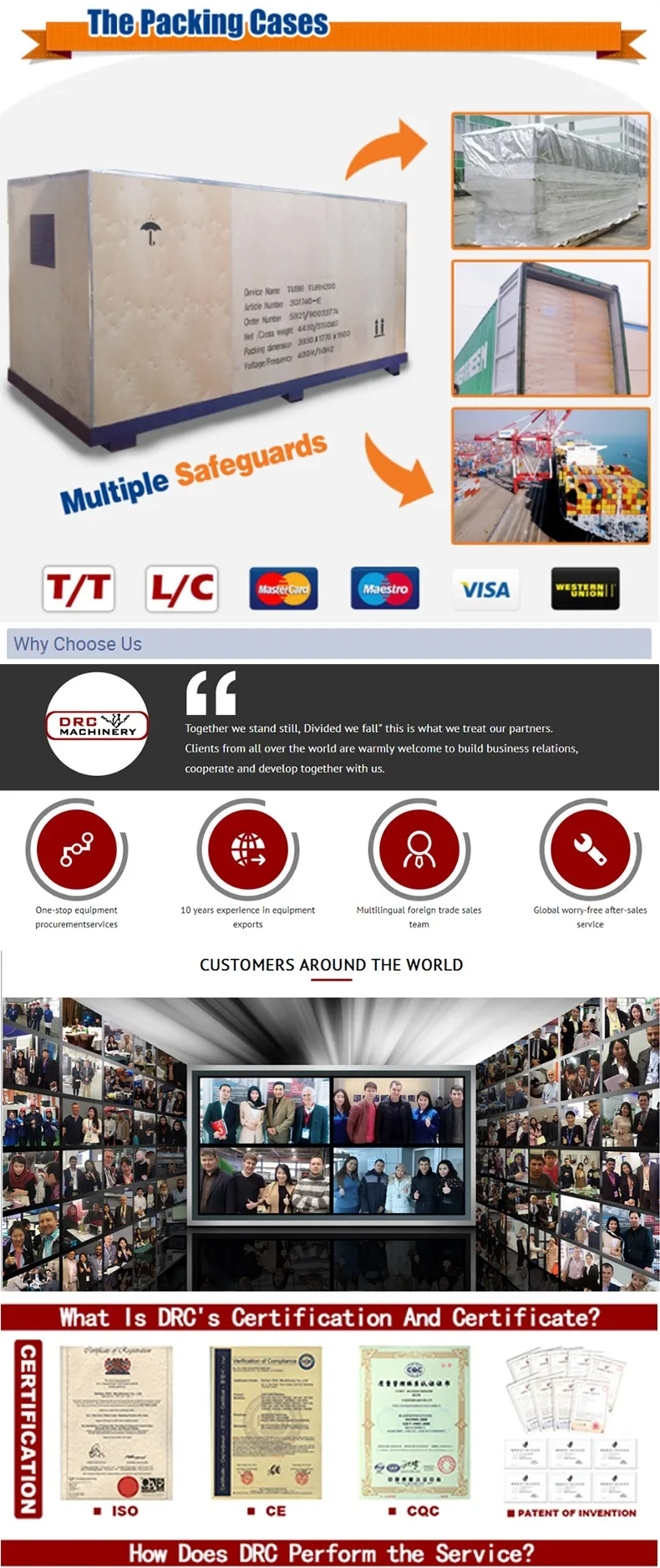

Packging & Delivery

Min Order1 piece

Briefing

Detailed

cnc lathe machine CKA61100A desktop cnc lathe

1.Company Introduction:

We are one of the leading machinery group specializing in producing heavy duty machine tools, it have five factories in China which mainly produce Vertical Lathe, Boring & Milling Machine, Heavy-duty Horizontal Lathe, both conventional and CNC types.

We have a group of professional engineers in charge of technology, manufacturing, installing and testing, so we can guarantee that our machines will put on good performance based on high quality.

2.Export Market:

Our products have been exported to more than 60 countries such as Canada, the U.S.A., Italy, France, Brazil, Bolivia, Chile, Russia, Romania, Saudi Arabia, Syria, Jordan, the U.A.E., Indonesia, Singapore, Thailand, India, Pakistan, South Africa, Egypt, Nigeria, Kenya and so on.

3.Our Belief:

We do believe we can create a win-win situation for both sides as long as we have come to a cooperation consensus. "Together we stand still, Divided we fall" this is what we treat our partners. Clients from all over the world are warmly welcome to build business relations, cooperate and develop together with us. Please feel free to contact us for details.

4.Product Introduction:

CKA series CNC lathes are designed with FANUC, SIEMENS, FAGOR, Dalian CNC and other CNC systems of the famous companies. The machines can work in the form of multiple replication cycling. As the general type, these machines can be used for the semi-finishing and finish machining of many kinds of spindles and disc parts. Besides, inside & outside ferrous, conical face, head face, grooving, chamfering, screw thread boring hole, reaming hole and all kinds of curve axially symmetrical.

5.Features:

1. The machine is designed with horizontal type, good sealing and safety standards. The basic parts like bed and leg of the machine adopts resin sand casting, artificial aging dealing which ensure the good stabilit

2. The machine works in high precision and longtime service by international highfrequencyquench.

3. Through famous CNC system, the machine has nice function, high precision and reliability.

4. By finite-element analysis, the headstock has developed &reasonable structure and strong pertinence. The supporting spindle use bearing and has the features of fast speed, high rigidity, nice accuracy, steady movement and low noise.

5. By designing with the ergonomics, the operating box can be set in rotating style, which makes it easy to operate for worker.

6. The machine can be lubricated by the centralizing system under scheduled time and quantity.

6.Specification:

7. Main Parts:

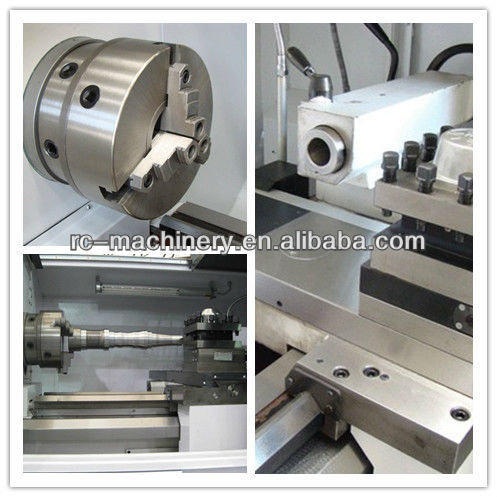

The main performance characteristics:

Guide rail high frequency quenching, high hardness and wear resistance,

Principal axis diagonal distribution contact ball bearing,high speed and high rigidity,

Instrument lathe replacement products, have a high price ratio, screw mid place ,

Standard configuration: Pneumatic spring chuck, Cutting knife,

Select configuration: Electric knife frame, Automatic feeding device, Tail seat.

Application:

Metal lathe machine is widely used in electrical equipment, Instrument apparatus industry, Cars, Motorcycle parts, Fastener bearing, Photographic equipment, movie mechanical, hardware various clocks and watches,The glasses, Stationery, electric machinery, Valves, Gas pipe fittings and other high precision machining and manufacturing of complex parts, Is a hardware machinery processing industry the most ideal efficient equipment. Is a hardware machinery processing industry the most ideal efficient equipment.

8. Why Choose Us:

9. After-sales Service and Commitment to Quality:

a. The date of final acceptance of the machine, the vendor of the product free of charge three packs a year (the buyer causes damage will be charged the cost of).

b. Machine fails, the user information of the seller can accurately determine the cause of the malfunction and treatment measures, given immediately reply sent to the scene to deal with such as could not determine the cause, within 48 hours, to solve the failure so far.

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

You need a product

Related Searches

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C