5 Axis CNC Gantry Milling Machining Center

group nameGantry Machining Center

-

Min Order1 piece

brand nameDRC

modelGMF8034R

payment methodL/C, T/T

-

update timeThu, 14 Nov 2019 13:13:07 GMT

Paramtents

Dimension(L*W*H): 19000×7500×6500mm

Weight: 50000KG

Machine Type: CNC gantry milling machine

Belt drive/ max. speed: 3750 r.p.m gantry milling machine

Spindle specifications: BT50/Φ190 (Belt)

Workbench size: 8000/2600 mm

Travel for X/Y/Z axis: 8200/4000(3400 mm

T-slot width : 30-28×250(Translot) mm

Motor power of spindle: 30/37kw

CNC system: FANUC Oi MD

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Heavy Duty CNC Gantry Milling Machine GMF3025R Gantry Machining Center Precision Parts Processing Milling Machine

Gantry Machining Center Main Feature

Gantry milling machine 5 axis machining center cnc inherits the advantages of rigid rigidity, structural symmetry and strong stability of the traditional gantry machine frame. It introduces the international advanced dynamic rigid design concept and optimizes the design of moving parts. The machine tool has large torque and good fast response characteristics, and is suitable for various mechanical processing fields such as automobile, mold, aerospace, military, and hardware.

Heavy Duty CNC Gantry Milling Machine Overall layout

The overall layout of the machine tool is fixed-column fixed-column gantry frame structure, the base is fixed, and the workbench moves X-direction on the base; the column is fixed on the base, the beam is fixed on the column, and the sliding seat moves in the Y direction on the beam; the ram is in the sliding seat Move in the Z direction.

Structural Features of CNC Parts Processing Gantry Machining Center Milling Machine:

High rigidity and long-term precision retention:

1. The main large parts of the machine tool: the base, the workbench, the column, the beam, the sliding seat and the ram are all made of high-quality resin sand, high-strength high-quality cast iron, with a complete heat treatment process to eliminate residual stress and arrange enough reinforcement. The plate ensures sufficient strength, rigidity and high stability of the machine.

2. The XY axis adopts heavy-duty roller guide rail with strong rigidity and good dynamic precision.

3. The three-axis transmission adopts the Taiwan brand large-diameter grinding double-nut ball screw, which has compact structure, stable movement and high precision. The screw support is supported by a precision screw rod, and the two ends are pre-stretched to eliminate the loss of precision caused by thermal elongation.

4. The beam adopts a stepped structure. The cross section of the beam is large, the span of the guide rail is large, the distance from the center of the main shaft to the surface of the guide rail is short, the turning torque is small, and the structural rigidity is good.

5. The high-rigid Taiwan brand gantry special spindle, which is lubricated with grease, can make the spindle bearing have constant and reliable lubrication, which is economical and environmentally friendly and realizes long-term maintenance-free.

High precision, high dynamic response characteristics:

1. The spindle adopts high-precision angular contact ball bearing to achieve high rigidity and high spindle rotation accuracy.

2, XY axis roller guide, high precision, large load. The friction is low, the low-speed crawling phenomenon of the machine tool is reduced, the positioning accuracy is good, and high dynamic response characteristics are obtained at the same time.

3. The Z-axis adopts a dual-motor drive structure, and its dynamic response speed is higher than the traditional nitrogen balance and hydraulic balance structure, with stable operation and high precision.

high efficiency:The spindle speed can reach 5000rpm, and the three-axis rapid movement can reach 10/12/10m/min.

Large processing range:Compared with the same specification machine, the machine's 2.5m door width ensures a wider processing range.

Structure:CNC Gantry Type Milling Machine Center

The structure of machine tool is analyzed with ANSYS at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

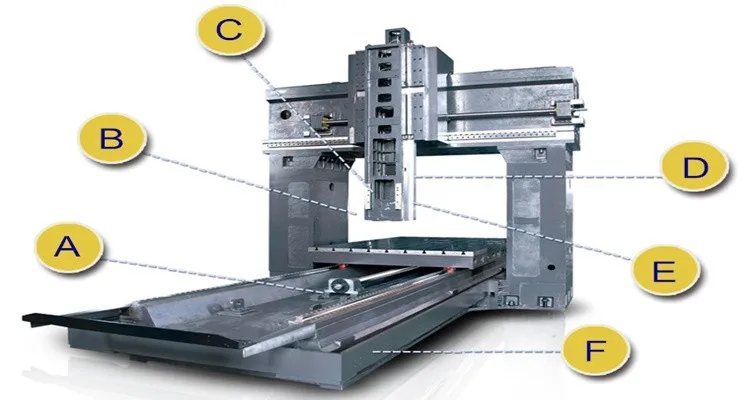

A1. Optional external encoder realizes closed loop control

A2. Screw supporting structure is designed for above more than 5 meters (including 5 meters) gantries.

B. All gear form main transmission is optional.

C. The optional Z axis rails, rail pre tensioning structure Guosheng patent technology.

D. Optional 90° milling head realizes five-face machining. Optional universal milling head realizes multi-angle machining

E. Optional German ZF gearbox widens machining range.

F. As standard each Guosheng gantry machining center is equipped with two spiral chip cleaners and one chain chip cleaner.

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C