Pipe thread heavy duty cutting cnc lathe machines

group namePipe Threading Lathe

-

Min Order1 piece

brand nameDRC

modelQK1319 Pipe Thrrad Lathe Machine

payment methodL/C, T/T

-

update timeWed, 06 Nov 2019 13:19:55 GMT

Paramtents

Max. Swing Over Bed: 630mm

Dimension(L*W*H): 2570*1620*1940mm

Max. Swing Over Carriage: 350mm

Guideway Width: 550mm

Power(W): 11KW

Control system: Fanuc

Weight: 3900kg

Max. Swing Diameter: 550mm

Spindle Hole: 200mm

Chuck: 4-jaw Chuck

Packging & Delivery

Min Order1 piece

Briefing

Detailed

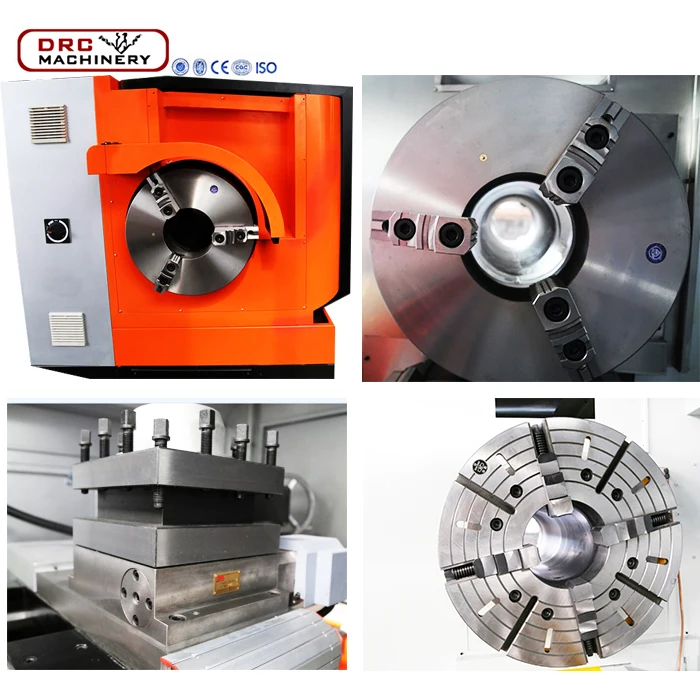

Double chuck big bore pipe thread lathe QK1319 horizontal CNC lathe

What Is DRC's CNC Lathe Machine?

Pipe thread heavy duty cutting cnc lathe machines

CNC pipe thread lathes are specially designed to meet the needs of China's oilfield, geological, mining, chemical and agricultural irrigation and drainage departments. The use of CNC pipe thread lathe is more economical and convenient than ordinary lathes to efficiently complete the cutting of various straight pipe and taper pipe threads, such as pipe joints, knots, casings, pipe pipes, mine pipes, water pump pipes, etc. The characteristics of petroleum geological, mining, chemical and agricultural irrigation and drainage departments, CNC pipe thread lathe can also process a variety of inch, metric, touch thread, turning a variety of shafts, disk parts, play the role of ordinary lathe, CNC pipe thread The lathe is the ideal machine tool for the petroleum, geology, chemical and agricultural sectors.This series lathe machine is widely used in industries including petroleum exploiting,coal and minerals mining,chemical piping and geological prospecting,it is high-efficiency equipment in processing and repairing drilling pipe,drilling rod,thread coupling and so on

What Is The Application Field of Lathe?

( More Detailed Picture of CNCLathe )

CNC PIPE THREADING LATHE Main Features:

1.Big spindle bore and double chuck allows clamp and process big diameter pipes;

2.Integral machine bed adopts high strength iron to relize high rigidity and precision;

3.Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance;

4.Carriage and guide way contact surface pasted with Turcite B to maintain long-term accuracy.

Standard Accessories:Fanuc CNCsystem,NC turret 4 position,Coolant system,Lubrication system,Lighting system,Mobile.hand-wheel,Semi-shield,Manual tailstock,Chuck,Rear support bracket, Pad iron etc.

Optional Accessories:CNC system(Simens,Fagor,GSK,KND),Turret(Servo,hydraulic,power),Chip conveyor,Air conditioner,Full-shield,Hydraulic tailstock,Chuck,Center rest,Follower rest,Signal light,Grinding attachment etc.

Customizing support:Painting color,headstock height,lathe bed length etc.

What Is The Details Of Pipe Thread CNC Lathe?

Pipe threading lathe Product advantages:

1.DRC Machinery use electric furnace smelting, resin sand molding casting technology,avoid sand holes, stoma casting internal defect effectively, all the accessories are assayed by imported spectrum analyzer, it assures the quality of the casting . The casting had been through second thermal aging treatment with good stability.

we can can absolutely ensure the casting quality after the United States imported equipment precision spectrometer analysis.

2.The bed of floor type is the whole structure. The rigidity and width of guide way on the bed of lathe is good enough. The guide way is through high-frequency quenching, the slide guide way joint SD compound soft belt. to make more wear-resisting and lower friction factor. The lead screw is the whole structure (not butt). The saddle is wider and thicker than before, the machine is running more stable. And the cutting ability is better.

With the super audio quenching treatment ,the hardness of Body guide rail can reach above HRC55 degrees, it can keep the hardness high accurate, and prolong the wear resistance and service life.

3.The 3 boxes of lathe were processed by Taiwan's CNC boring and milling machine center. The other tools are processed by CNC lathe and machine center to ensure the precision of the box and tools.

The lathe bed we produced is all research and development by our own engineers. These all can greatly increased the rigidity and are helpful to widen and Thicken the dragging plate,

4.The large plate guide guide rail (X) is also go through the super audio quenching treatment, so it increased hardness and then could guarantee the service life of equipment more efficiently.

The equipment will firstly tested by the laser interferometer imported from Britain to test repeated positioning accuracy of X, Z direction in order to make sure the accuracy. Then the whole machine will be tested according to the National standard whole machine.

Our enterprise have got the ISO9001-2008 quality system certification and the European Union CE certification.

Whole structure:The bed of floor type is the whole structure. The rigidity and width of guide way on the bed of lathe is good enough.

Accuracy test:First step of the accuracy test of the equipment is testing the repeat accuracy of X and Y axis with Renishaw laser interometer imported from Britain.

Electric furnace smelting:We use electric furnace smelting, resin sand molding casting technology,avoid sand holes, stoma casting internal defect effectively.

Send Inquiry Here to Get a Free Work-piece Sample!

Dalian R&C Machinery Co., Ltd.

E-mail:service..........com

WhatsApp:86-155-6681-6110

Address:No.27Shengming 3rd Road, Dalian Economical & Technological Development Zone, Liaoning, China

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C