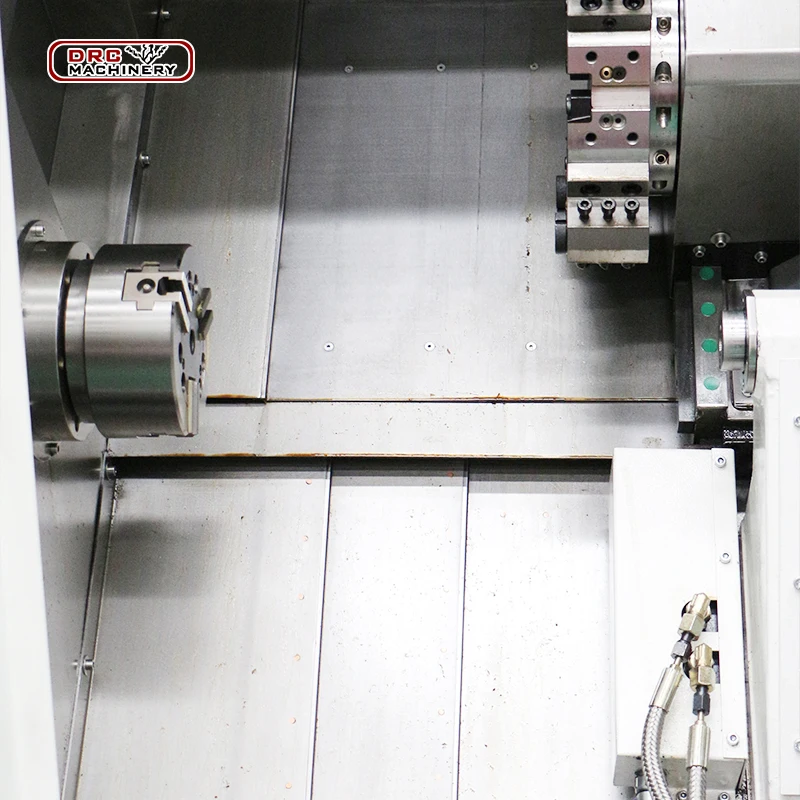

Because the bed body is formed by integral casting, the bed rail is inclined at 45° and has a large load-bearing cross-section.

Therefore, it has good rigidity and shock absorption to ensure high-precision cutting.

Slant Bed Horizontal CNC Lathe Turning Milling Center Turret Type Auto Lathe Machine

group nameSpecialized Machine for End Face

-

Min Order1 piece

brand nameDRC

modelJX-Z680

payment methodL/C, T/T

-

update timeMon, 08 Jun 2020 18:57:49 GMT

Paramtents

Maximum swing diameter 440mm

Cutting diameter (shaft/disk) φ260/φ300mm

Cutting length 450,430 mm

Product Type: CNC Lathe Machine

Spindle power 11/15kw

Machine Type: Slant CNC Lathe Machine

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Factory Price Slant Bed Horizontal CNC Lathe Turning Milling Center Turret Type Auto Lathe Machine

Factory Price Slant Bed Horizontal CNC Lathe Turning Milling Center Turret Type Auto Lathe Machine

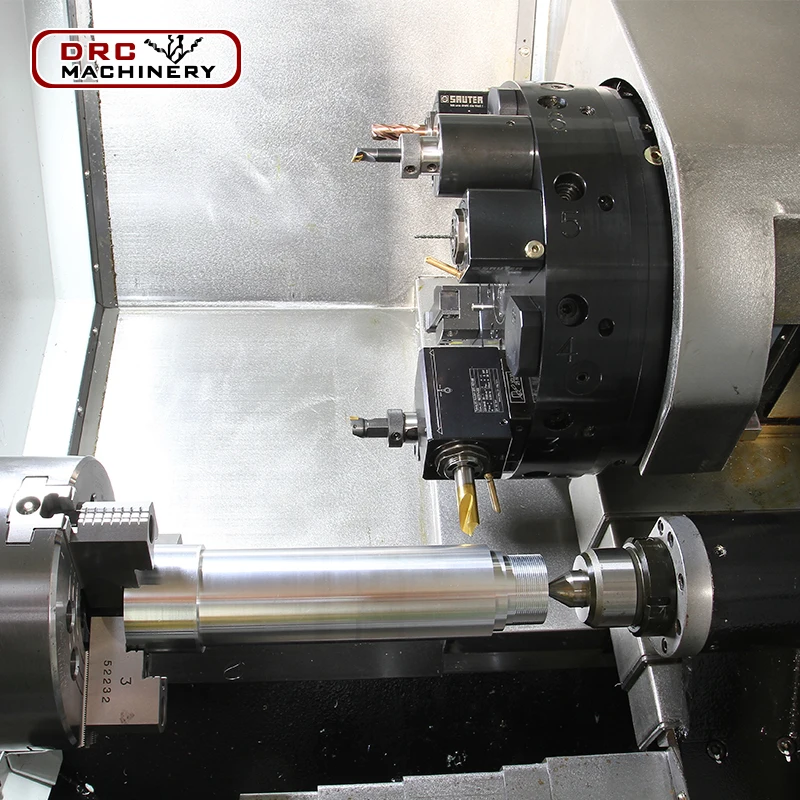

The CL-20A horizontal CNC lathe is a two-axis linkage, semi-closed-loop CNC lathe produced by our company. The main machine bed is formed by integral casting. The bed rail is inclined at 45° and has high rigidity. The control system uses FANUC 0i-TF (5), GSK and other systems and AC AC servo drive can perform various turning processes on shaft parts within φ260mm and disk parts within φ300mm.

CNC Lathe Product Introduction:

The new CL series of CNC slant bed lathes with rigid cast-iron structre hardened(50-52HRC) and ground guarantee high precision and stability.The machine bed is made of heat stabilised cast-iron.Varous configuration are available with sindles from ASA 5" to ASA 15",power up to 30kW and tuming length up to 3000mm,A wide range of options and accessories allow the machine to be highly customised for very accurate and reliable machining.

CL-20a CNC Mecanisme de Tour Features:

high steel nature structure design.

high efficiency, low noise.

high speed, high steel nature spindle.

high reliability of knife rest.

precise fast speed drive trasmission.

centralized lubrication system.

whole seal protection.

chip removal coolant system.

High rigidity structure design:

High efficiency, low noise design:

The main drive system of the machine tool uses an AC servo motor, coupled with a high-efficiency parallel V-belt to directly drive the spindle. The noise problem caused by the gearbox transmission chain is avoided.

High-speed, high-rigidity spindle:

The front and rear ends of the main shaft adopt NSK precision high-speed main shaft bearing set, and apply proper preload,together with the best span support and box-type main shaft box, so that the main shaft has high rigidity and high-speed operation capability.

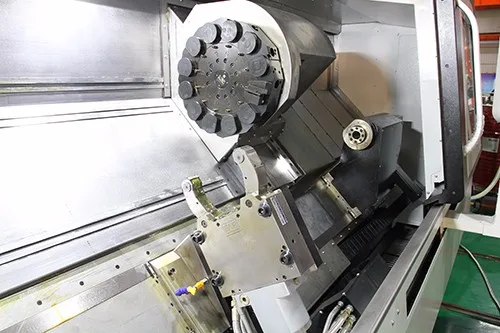

Highly reliable tool holder:

High-rigidity hydraulic tool table with high reliability and repeated positioning accuracy.

Precise and fast vertical and horizontal drive:The machine tool uses ball screws and linear rolling guide rails. The transmission efficiency is high, the accuracy is maintained well, the machine tool holder moves fast and stable, and the positioning accuracy

is high.

Automatic centralized lubrication system:

It can ensure continuous and effective lubrication of guide rails and ball screws.

Fully enclosed protection:It avoids the leakage of coolant and provides the operator with a safe and comfortable working environment.

Chip cooling system:The independent chip cooling system is equipped with a large-flow cooling pump and chain chip removal device to provide forced cooling and automatic chip removal for turning.

E-mail:service..........com

WhatsApp:86-155-6681-6110

You need a product

You May Like

- Nearest port for product export

- Dlian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C