1.Energysaving sand and stone production line with high capacity can be simplysummarized as crushing and sorting, mainly from the conveyor, feeding,crushing, screening, sand and other aspects of aggregate production lineintroduced aggregate.

2.Thechoice of crushing equipment depends on the characteristics of ore raw materials,the local market demand for gravel products and production capacity of theproduction line.

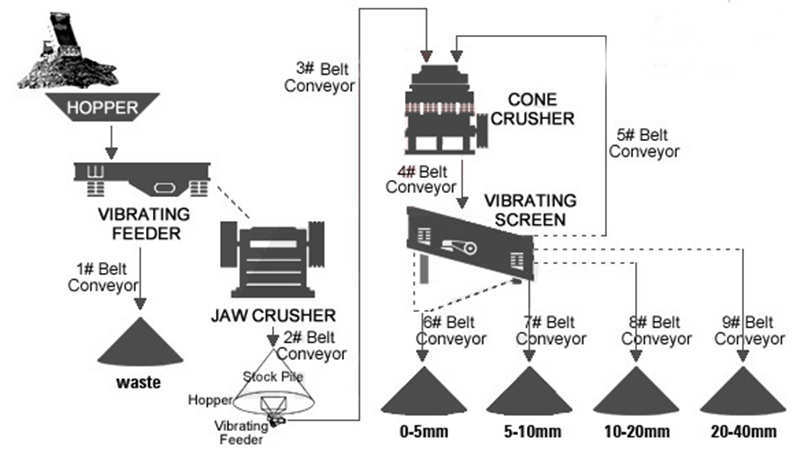

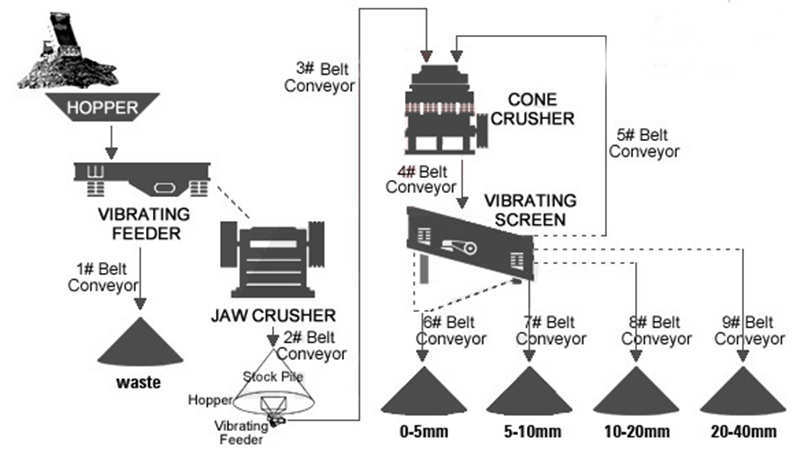

3.Energy saving sand and stone production line production process is as follows:

a.Largestone by the silo by the vibrating feeder evenly sent to the jaw crusher forcoarse crushing, coarse crushed stone by the conveyor belt to the impactcrusher for further crushing.

b.Crushedstone by the belt conveyor Sent to the vibrating screen for screening,screening out several different specifications of the stone, meet therequirements of the size of the stone conveyor belt conveyor, the finishedproduct sent to finished heap.

c.Donot meet the requirements of stone by the conveyor belt back to the impactcrusher to break again to form closed-loop multiple cycles.

d.Finishedparticle size can be combined in accordance with the needs of users andgrading, to protect the environment, can be equipped with auxiliary dustremoval equipment.

a.Theshape of the final product, with excellent quality.

b.Mudand powder content can be controlled.

c.This sandproduction line has the characteristics of high automation, low operating cost,high crushing rate, high productivity, and little pollution, etc. It is energysaving and is convenient to maintain.

d.Sand made by oursand production line is of equal size, good shape and reasonable distribution,complying with national building sand standard.

e.Due to reasonablematching of different levels of crushing machines spatial arrangement, ourcrushing and screening plant has the features of small floor space, higheconomic efficiency. The crushed stones are of high quality, and the outputrate of stone powder is low.

f. Meanwhile, oursand production line is equipped with electronic control system which ensuressmooth discharging, reliable performance, high efficiency and energyconservation.

g.Our seniorengineers design each production line according to different customers.

1.Aggregates with grain size larger than 5mm are called coarse aggregates, andthere are two kinds of gravel and pebble commonly used. Particle size grading:5-10,10-20,20-31.5.

2.The aggregate with the grain size below 5mm is called fine aggregate. Accordingto theproduction of sand is divided into natural sand and machine-made sand.

3.Aggregates as the main raw material in concrete because of its good hardnessand stability of chemical properties ,It is play a role of the skeleton andsupport in the building. Widely used in housing, roads, roads, railways,engineering and other fields.

4. Sand and stone production line with high capacitycan be used for hard limestone, granite, basalt, river gravel, smelting slagand other materials, aggregate and artificial sand making operations,forHydropower Station, building materials, highways, urban construction and otherindustries.

5.Accordingto different process requirements, various types of equipment combined to meetcustomer's different process requirements.

1.Vibrating feedingequipment

Thistype of vibrating feeder can continuously feed the material to the crushercontinuously and make rough screening of the materials.

2.Crusher

1.Accordingto the broken principle can be divided into two categories: extrusion crusherand impact crusher. Extrusion crusher (such as gyratory crusher, jaw crusher,cone crusher) is suitable for rock with high hardness and abrasive index (suchas granite, quartz, diabase, basalt).

2.Impactcrusher (such as the impact crusher, vertical shaft crusher, hammer impactcrusher) to adapt to the hardness, abrasion index medium or low rock (such aslimestone, dolomite, etc.).

1)jaw crusher

primarycrushing of hard rocks and block materials

2) impact crusher

3)PYFB-1324 Composite conecrusher

PYFB-1324compound cone crusher used in mining, cement, sand and gravel industry, formedium, fine broken, the pressure of 350 MPa in the following mine rocks, suchas iron ore, non-ferrous metal ore, basalt, granite Limestone, sandstone,pebble stool.

3.Circular screen/vibratingscreen---sieve the crushed stone into differentsizes

4.Sand making equipment---Mainlyvertical shaft sand or rod mill.

1) Vertical axis form of sandmaking machine

Sandmaking machine is widely used in a variety of fine ore broken. Sand makingmachine is widely used in medium and fine crushing fields of various hard andspecial hard materials such as ore, cement, refractory material, bauxiteclinker, emery, glass raw material.

2) Rod mill

Rodmill is mainly used for preparation of sand. The material is raised to acertain height, falling state was dropped, the need for grinding of thematerial from the feeding Department of continuous into the cylinder, thegrinding of the grinding medium is moving, and through the overflow and thepower of continuous feeding the product out of the machine for the nextprocessing step.

3) Screwclassifier

Screwclassifier used for the production of gravel in the process of particle sizegrading, and used in conjunction with mining machinery. Screw classifier Widelyused in the ore dressing and ball mill with a closed loop, diversion of ore, orfor gravimetric ore in the classification of ore and fine mud, and metalmineral processing process for particle size grading, and washing operations inthe deslimation, dehydration and so on. The spiral classifier has thecharacteristics of simple structure, reliable operation and convenientoperation. Also used for gravel operations in the deslimation or dehydration.

Maximum Feeding Size(mm) | Capacity(t/h) | Vibrating Feeder | Jaw Crusher | Fine Crushing Equipment (Impact Crusher) | Vibrating Screen | Conveyor Equipment(m) | Installed Power(KW) | |

| |

| |

340 | 30 | GZD2511(3kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1236(15kw) | 60-90(20kw) | 120 | |

340 | 50 | GZD3117(10kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 | |

420 | 80 | GZD3617(10kw) | PE500×750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 | |

480 | 100 | GZD4321(13kw) | PE600×900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 | |

560 | 150 | GZD4321(13kw) | PE750×1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 | |

630 | 200 | GZD4321(13kw) | PE900×1060(110kw) | PFB1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 | |

630 | 250 | GZD5027(17kw) | PE900×1060(110kw) | PFB1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 | |

630 | 300 | GZD5027(17kw) | PE900×1200(110kw) | PFB1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 | |

700 | 350 | GZD5027(17kw) | PE1000×1200(132kw) | PFB1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 | |

700 | 450 | GZD6223(28kw) | PE1000×1200(132kw) | PFB1214/2(300kw) | 3YZ2145/2(60kw) | 350(60kw) | 600 | |