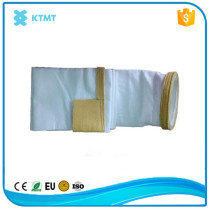

Homopolymeric Acrylic (PAN) Dust Filter Bags

group nameDust Filter Bag

-

Min Order500 piece

brand nameKTMT

payment methodL/C, Western Union, T/T, Paypal

-

update timeSat, 30 Sep 2017 09:00:01 GMT

Paramtents

Fiber Materials PAN-Acrylic Homopolymer

Scrim PAN

Standard Finish Options Heat Set, Singed, Glazed, PTFE membrane

Weight oz/yd² (g/m2) 14.75-16.22 (500-550)

Thickness Inch (mm) 0.071-0.091 (1.8-2.3)

Air Permeability CFM@ ½" W.G125PA (m³/m².min@200 12-21 (6-10)

Packging & Delivery

Size35cm x 35cm x 35cm

Weight15.00kg / piece

Min Order500 piece

Briefing

Detailed

Homopolymeric

Acrylic (PAN) Dust Filter Bags

Introduction:

Using the finest

fiber material possible in the market and high-speed modern needling equipment,

we manufacture our own filter media for our dust filter bags guaranteeing the

highest quality, reliability, and consistency

A wide range of surface finishes and chemical treatments that aid in the

collection and release of the dust from the bags

Ultrasonic welded seam for increased efficiency and reinforced mechanical

strength

Our laboratories are equipped with sophisticated testing equipment used to

analyze and evaluate all aspects of your process and application

Custom

fabricated bag designs to meet the unique needs of your bag house installation

Specification:

|

Fiber Materials |

PAN-Acrylic Homopolymer |

|

|

Scrim |

PAN |

|

|

Standard Finish Options |

||

|

Weight |

14.75-16.22 (500-550) |

|

|

|

0.071-0.091 (1.8-2.3) |

|

|

Air Permeability |

||

|

Tensile Strength |

Warp MD |

80 (700) |

|

Weft CD |

114 (1000) |

|

|

Tensile Elongation (%) |

Warp MD |

≤25 |

|

Weft CD |

≤45 |

|

|

Thermal Shrinkage (%) at max continuous temp. |

Warp MD |

≤1 |

|

Weft CD |

≤1.5 |

|

|

Max. Operating Temperature oF (oC) |

Continuous |

260 (127) |

|

Surge |

284(140) |

|

|

The data are based on laboratory conditions. |

||

Media Feature:

-A type of acrylic,

functions at higher temperatures

-Good resistance to most

mineral and organic acids.

-Acrylic resistance to

alkalis is inferior to most fibers except natural protein fibers such as silk

and wool.

-Acrylic has good resistance

to most oxidizing agents and is superior to polyamides and protein fibers in

this respect.

-Excellent resistance to

most common organic solvents.

-High resistance to

hydrolysis and good temperature resistance.

-Not recommend for high

concentration of strong alkalis at high temperatures.

-Acrylic is more costly

than polyester and polypropylene.

-Continuous operating

temperature 260℉ (127°C)

Application:

Ø Power Generation

Ø Paper, Pulp & Woodworking

Ø Cement, Mining & Rock Products

Ø Waste Incineration

Ø Chemicals & Pharmaceuticals

Ø Metals & Foundry

Ø Food & Beverages

Ø Custom OEM Applications

Ø Most popular applications include: dryers, electric furnace, aluminum reduction and primary or secondary smelting.

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union, Cash