Melting

The key to the production of high quality ductile iron is the acquisition of high temperature and low

sulfur pure iron. In China, the main production equipment is the cupola, and the iron water is not

pretreated by desulphurization, and the second is the high purity of raw iron and the poor quality of

coke. The molten iron is melted by a cupola. It is desulphurized by the furnace and then heated in

the induction furnace and the composition is adjusted. A vacuum direct reading spectrometer has

been widely used to detect the composition of molten iron in China.

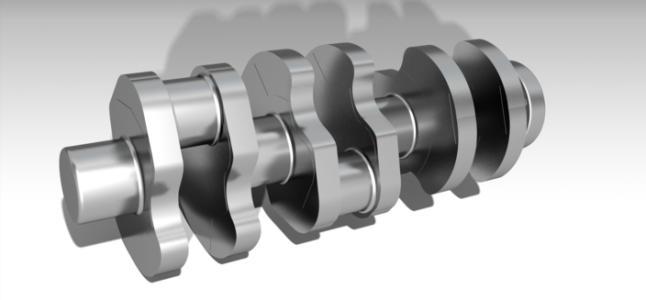

modelling

The air impact molding process is superior to the clay sand molding process, and the crankshaft

castings with high accuracy can be obtained. The sand moulds made by the process have the

characteristics of no rebound deformation and so on, which is especially important for multi crank

crankshafts. A number of crankshaft manufacturers in China have introduced air impact molding

technology from Germany, Italy and Spain. However, only a few manufacturers have introduced the

entire production line.

Electroslag casting

The electroslag remelting technology is applied to the production of crankshaft, so that the

performance of the cast crankshaft may be comparable to that of the forging. It has the

characteristics of fast development cycle, high utilization rate of metal, simple equipment and

superior product performance.

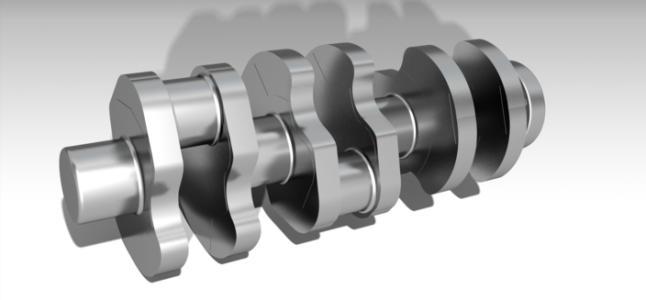

Forging technology

In hot forging press, electro hydraulic hammer for automatic line host is the development direction

of the crankshaft forging production, the production line will be widely used in precision shearing

blanking roll forging billet (Xie Hengzha), medium frequency induction heating, finishing machine

hydraulic press and other advanced technology, at the same time with the manipulator, conveyor

belt, back to change die device and other auxiliary table, the formation of flexible manufacturing

system (FMS). Through FMS, the workpiece and die can be replaced automatically and the

parameters are adjusted automatically, and it is continuously measured during the working process.

The data of the thickness and maximum pressure of the forgings are displayed and recorded and

compared with the fixed value, and the optimal amount of deformation is selected to obtain the

high quality products. The whole system is monitored by the central control room to realize the

unmanned operation. The forging of the crankshaft with the forging method has the full fiber of the

inner metal flow line, which can increase the fatigue strength by more than 20%.