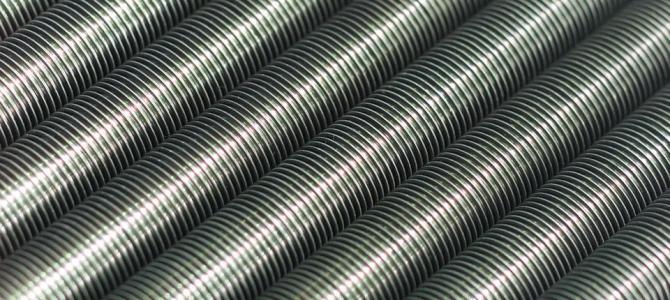

Custom oxygen free copper high efficiency heat exchanger tube

group namehardware fitting

-

Min Order1 piece

brand nameHicoin

payment methodL/C, D/A, D/P, MoneyGram, T/T, Paypal

-

update timeTue, 06 Mar 2018 16:14:02 GMT

Paramtents

Place of Origin TianjinChina

Port OR Air port Tianjin,Shanghai,New York,Etc

Molding process Low pressurecasting OR CNC

Types of special casting Metal mold casting

Package Wooden cases, iron cases or according to custom stransportation and customer needs

Specific ations According to customer drawing need

Material used in manufacturing bronze

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Tian Jin, Shang Hai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal