Custom Matte Finish Black Plastic Injection Machinery Parts , ABS PC Plastic Injection Molding

group namePlastic Injection Mold

-

Min Order1 set

brand nameLONGXIANG

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeFri, 30 Mar 2018 14:24:30 GMT

Packging & Delivery

Min Order1 set

Briefing

Detailed

Longxiang Group Limited was established in Dongguan city in 1998. After over 15 years of hard work, Longxiang has grown to be one of the highest reputable mould maker in China with 120 employees’ 5000 sq. Meter working shop.

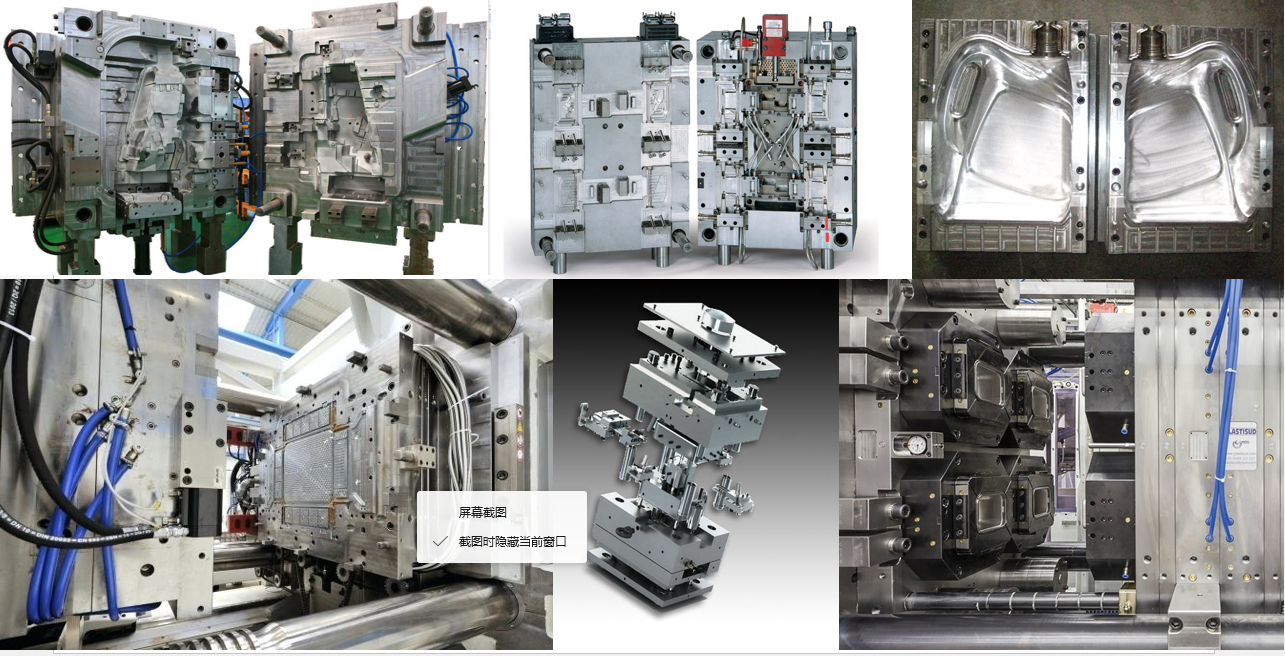

Up to now, Longxiang has exported about 2400 sets of moulds to 38 countries. The moulds we made include automotive parts (dashboards, inner decorating accessories, etc.), electrical appliances (washing machine, air conditioner, refrigerator, television, etc.), IT industry products (cell phones, computer, etc.), householder products (micro-wave oven, juicer, etc.), office accessories (telephone, printer, etc.) as well as other various of products. We look forward to participating at the success of your next project.

Mold Specification

|

Mold Material |

45#,P20 steel, 718, 2738, H13, |

|

Mold Type |

Plastic Injection Molding |

|

Product Material |

ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

|

Mold Standard |

HASCO, DME, MISUMI, JIS, LKM, etc. |

|

Mold Tooling Equipment |

Lathe,Milling,Grinder,Drill,CNC,EDM, |

|

Injection Mold Machine |

80T to 2800T |

|

Product Weight |

50-20000g |

|

GateType |

Side Gate, Sub Gate, Direct Gate, |

|

Runner Type |

Cold Runner or Hot Runner |

|

Cavity |

Single or Multi cavities |

|

Treatment |

Heat treatment and Nitriding,polish ect. |

|

Mold Life |

45#:50,000 to 100,000 shots |

|

P20:100,000 to 200,000 shots |

|

|

718: 200,000 to 300,000 shots |

|

|

H13: 300,000 to 500,000 shots |

|

|

Lead Time |

Generally mold making will take around 30 days |

|

Package |

Wooden packing box for molds |

Tooling Developing Procedure:

1. Quotation: We need your require clearly

2. Negotiation: Material, cavity, price, delivery time, payment term, etc.

3. Order: According your own design or choice our design

4. DFMEA: Deign failure mold & Effect analysis to reduce risk

5. Mold design: 2D/3D drawing

6. Cutting Tooling Notice: After customer approve the mould design will start making mould

7. Weekly Report: We will update the mold schedule every week

8. Sample Confirm: Send you sample for conform it, if not satisfied by customer. We modify mould.

9. Delivery Mold: Delivery mould after customer approve sample and arrange shipment

FAQ

1. Q: Which kind of product can you do?

A: Plastic injection molding and mass production for plastic parts.

2. Q: Which kind information need for quotation?

A: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample or tell me your idea,we will help to finish the 3D drawing design.

4. Q: How long will be the injection mold finished?

A: Usually it will take about one month to finish the mold.

5. Q: How about the samples?

A: After mold finished, We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.

6. Q: How about the mould modify?

A: You can tell us your comment about the samples after you receive them.If there is any dimension different from the drawing,we will modify the mold for free in our side and then make the new samples.

7. Q: How about the proprietary rights of the plastic injection mold?

A: Customer paid the mould so it all belong to Customer.

8. Q: How about the surface treatment?

A: Metallization (chrome, gold, silver) / Painting (hand, screen, automated) /Vacuum plating / Lithography / Custom texturing/ Hydrographics

You need a product

You May Like

- Nearest port for product export

- Guangzhou, Shenzhen, Hongkong

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP

- Acceptable payment methods

- T/T, L/C, MoneyGram, PayPal, Westem Union, Cash