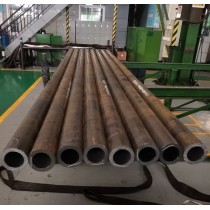

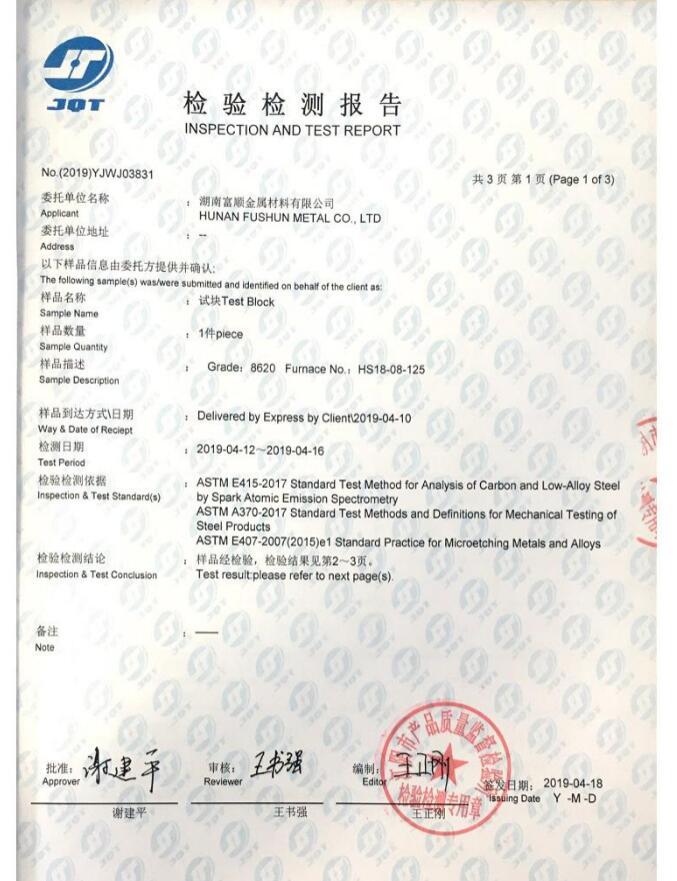

ASTM A519 8620 Hot Rolled Alloy Steel Seamless Steel Tube

group nameHollow Bars

-

Min Order1 piece

brand namefushun

payment methodT/T, L/C, D/P D/A

-

update timeThu, 14 May 2020 15:40:41 GMT

Paramtents

OD 40-400MM

WT 5-30MM

Delivery condition QT

Surface condition peeled

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Specifications

Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

ASTM A29 | 8620 | 0.18-0.23 | 0.7-0.9 | 0.035 | 0.040 | 0.15-0.35 | 0.4-0.7 | 0.4-0.6 | 0.15-0.25 |

DIN 1654 | 1.6523/ | 0.17-0.23 | 0.65-0.95 | 0.035 | 0.035 | ≦0.40 | 0.4-0.7 | 0.4-0.7 | 0.15-0.25 |

EN 10084 | 1.6523/ | 0.17-0.23 | 0.65-0.95 | 0.025 | 0.035 | ≦0.40 | 0.4-0.7 | 0.35-0.70 | 0.15-0.25 |

JIS G4103 | SNCM220 | 0.17-0.23 | 0.6-0.9 | 0.030 | 0.030 | 0.15-0.35 | 0.4-0.7 | 0.4-0.65 | 0.15-0.3 |

BS 970 | 805M20 | 0.17-0.23 | 0.6-0.95 | 0.040 | 0.050 | 0.1-0.4 | 0.35-0.75 | 0.35-0.65 | 0.15-0.25 |

Properties | Metric | Imperial |

Tensile strength | 530 MPa | 76900 psi |

Yield strength | 385 MPa | 55800 psi |

Elastic modulus | 190-210 GPa | 27557-30458 ksi |

Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Izod Impact | 115 J | 84.8 ft.lb |

Hardness, Brinell | 149 | 149 |

Hardness, Knoop (converted from Brinell hardness) | 169 | 169 |

Hardness, Rockwell B (converted from Brinell hardness) | 80 | 80 |

Hardness, Vickers (converted from Brinell hardness) | 155 | 155 |

Machinability (hot rolled and cold drawn, based on 100 machinability for AISI 1212 steel) | 65 | 65 |

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A