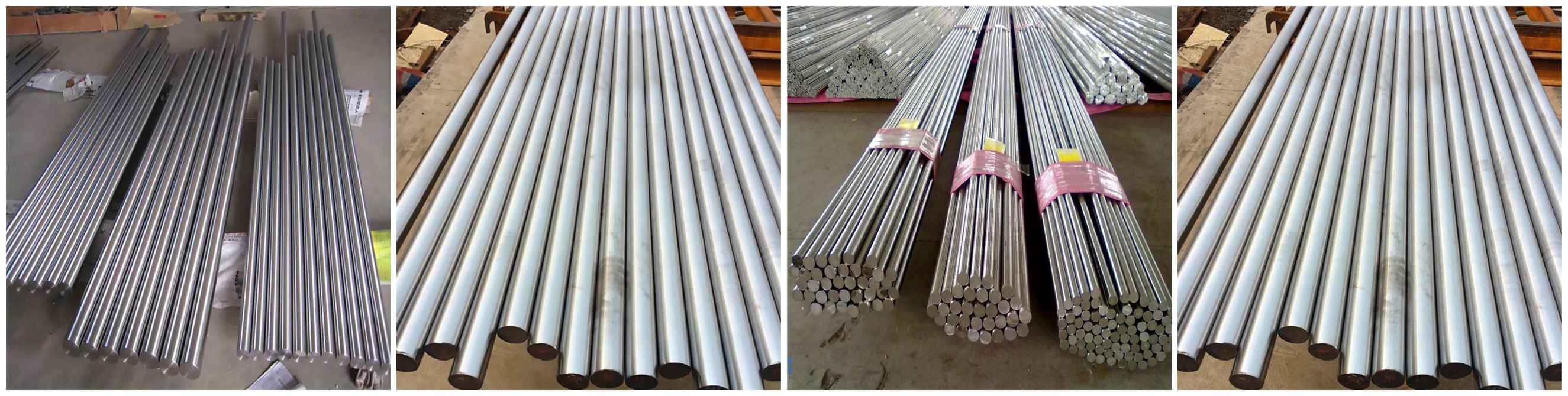

Incoloy 825 UNS N08825 2.4858 NiCr21Mo Nickel Alloy Bar

group nameNickel Alloy Bar

-

Min Order1 piece

brand namefushun

modelIncoloy 825 UNS N08825 2.4858 NiCr21Mo

payment methodL/C, T/T

-

update timeTue, 23 Jun 2020 10:27:47 GMT

Paramtents

Diameter Range 10-300mm

Length Range 1000-9000mm

Delivery Condition Annealed

Surface Condition Bright

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Introduce

UNS N08825 Incoloy 825 is a nickel-iron-chromium alloy that contains small amounts of titanium, copper, and molybdenum. Incoloy® 825’s chemical composition provides great resistance to many corrosive environments, such as pitting, crevice corrosion, intergranular corrosion, and stress- corrosion cracking. Incoloy 825 nickel alloy has good mechanical properties from moderate to high temperatures, with a hot- working range of 1600 to 2150º F. Alloy 825 also maintains good weldability for all conventional processes.

Applications

Nickel alloy UNS N08825 has many different industrial applications, some of which include: Propeller shafts, Phosphoric acid evaporators, Tank trucks, Hot vessels for food, water, sea water, Sulphuric acid piping and vessels, Marine exhaust systems

2. Plate, Sheet and Strip: BS 3072NA16, BS 3073NA16, ASTM B 424, ASTM B 906, ASME SB 424, ASME SB 906, DIN 17750, VdTÜV 432, ISO 6208.

3. Pipe and Tube: BS 3074NA16, ASTM B 163, ASTM B 423, ASTM B 704, ASTM B 705, ASTM B 751, ASTM B 775, ASTM B 829, ASME SB 163, ASME SB 423, ASME SB 704, ASME SB 705, ASME SB 751, ASME SB 775, ASME SB 829, ASME Code Case 1936, DIN 17751, VdTÜV 432, ISO 6207.

4.Others: ASTM B 366, ASME SB 366, DIN 17744

Chemical Composition

Ni | Fe | Cr | Mb | Cu | Ti | C | Mn | S | Si | Al |

38.0-46.0 | 22.0 min | 19.5-23.5 | 2.5-3.5 | 1.5-3.0 | .6-1.2 | 0.05 max | 1.0 max | 0.03 max | 0.5 max | 0.2 max |

Mechanical Properties

Form | Condition | Ultimate Tensile Strength, ksi (MPa) | Yield Strength at 0.2% offset, ksi (MPa) | Elongation in 2" or 4D, percent |

Sheet Plate Strip, Bar | Annealed Annealed Annealed | 100 (689) 95 (655) 85 (590)a | 55 (379) 45 (310) 35 (240)a | 39 44 30a |

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A