O7 Cold Working Tool Steel

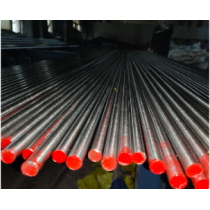

group nameTool Steel Bars

-

Min Order1 piece

brand namefushun

modelO7

payment methodT/T, L/C, D/P D/A

-

update timeTue, 25 Apr 2023 10:53:41 GMT

Paramtents

Delivery Condition +N or +A or +QT

Surface Condition black or turned or polished

Packging & Delivery

Min Order1 piece

Briefing

Detailed

O7 Cold Working Tool Steel

Introduction:

O7 Cold Working Die Steel is one kinds of oil hardening cold working die steel, which consists of chromium and manganese, and has higher tungsten content than grade O1. The O7 steel has the best wear resistance among the O series steels, however, it has relatively low hardenability.

Cutting and punching tools for sheet thickness up to 6 mm, also for paper and plastics, roll shear blades for sheet thickness up to 6 mm, small bending and drawing tools, thread cutting tools, reamers, woodworking tools, gauges and other measuring tools, small inserts and plastic moulds.

ASTM A681 – 08 Standard Specification for Tool Steels Alloy.

ASTM | Material No. | EN | JIS | GB |

O7 | 1.2419 | 105WCr6 | SKS31 | CrWMn |

Steel Grade | C | Si | Mn | P | S | Cr | V | W | Mo |

O7 | 1.10-1.30 | 0.10-0.60 | 0.20-1.00 | 0.030 max | 0.030 max | 0.35-0.85 | 0.15-0.40 | 1.00-2.00 | 0.30 max |

SKS31 | 0.95-1.05 | 0.35 max | 0.90-1.20 | 0.030 max | 0.030 max | 0.80-1.20 | / | 1.00-1.50 | / |

105WCr6 | 1.00-1.10 | 0.1-0.40 | 0.80-1.10 | 0.030 max | 0.030 max | 0.90-1.10 | / | 1.00-1.30 | / |

CrWMn | 0.90-1.05 | 0.40 max | 0.80-1.10 | 0.030 max | 0.030 max | 0.90-1.20 | / | 1.20-1.60 | / |

FORGING: Hot forming temperature: 1050-850oC

SOFT ANNEALING: Heat to 720-750oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 230.

STRESS RELIEVING:Stress relieving to remove machining stresses should be carried out by heating to approx. 650oC, holding for 1-2 hours at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

HARDENING:Harden from a temperature of 800-830oC followed by oil quenching or warm bath quenching approx. 200oC. Hardness after quenching is 63-65 HRC.

TEMPERING: Tempering temperature: See the data bellow.

Tempering Temperature | Hardness(HRC) |

100oC | 64 |

200oC | 61 |

300oC | 58 |

400oC | 54 |

500oC | 49 |

600oC | 41 |

650oC | 30 |

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A