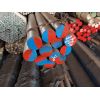

1.4528, X105CrCoMo18-2, Stainless Plastic Mould Tool Steel Bar

group nameTool Steel Bars

-

Min Order1 piece

brand namefushun

payment methodL/C, T/T

-

update timeTue, 27 Jun 2023 15:24:37 GMT

Paramtents

Process hot rolled or hot forged

Delivery Condtion annealed

Surface Condition smooth, bright

Packging & Delivery

Min Order1 piece

Briefing

Detailed

1.4528, X105CrCoMo18-2, Stainless Plastic Mould Tool Steel

Product Description

Corrosion-resistant, martensitic chromium steel with high carbon-content, cobalt-, molybdenum- and vanadium-addition.

l TOOL STEELS

l HARDENABLE CORROSION RESISTANT STEEL

l Plastic Mould Cold Work

Properties

l Toughness & Ductility : good

l Wear Resistance : very high

l Machinability : good

l Dimensional stability : good

l Polishability : good

l Corrosion resistance : high

Applications

l Packaging

l Food industry like extrusion screws, can closing rolls

l Screws for plastic injection and back flow valves

l Cutting-typical instruments and knives Moulds for plastic injection (PIM)

l Pharmaceutical industry like pill punches and –dies

l Extrusion screws for plastic processing

l PIM and screws for processing of GF-reinforced plastics

l Hot runner systems

Material designation

1.4528

X105CrCoMo18-2

Chemical composition (wt. %)

C | Si | Mn | Cr | Mo | V | Co |

1.08 | 0.40 | 0.40 | 17.30 | 1.10 | 0.10 | 1.50 |

Delivery condition

Annealed Hardness (HB) max. 285

Heat treatment

Stress relieving

Temperature 650 °C | 1,202 °F After warming up completely, keep at temperature for 1 to 2 hours in a neutral atmosphere. Slow furnace cooling

Hardening and Tempering

Temperature 1,000 to 1,060 °C | 1,832 to 1,940 °F Holding time after complete soaking, max. 30 minutes / 25 mm cross section.

Temperature 150 to 350 °C | 302 to 662 °F Tempering treatment required after hardening to the desired working hardness. Tempering of min. 2h after complete soaking. Tempering shall be made immediately after hardening. After each tempering a cooling RT shall be done.

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A