Solar Panel Materials Various Thickness Solder Wire bus bar

group nameSolar panel raw material

-

Min Order1 piece

brand namesufusolar,saikangguangdian,shanggui

payment methodL/C, T/T

-

update timeWed, 31 Oct 2018 13:19:28 GMT

Paramtents

Model Number Soldering ribbon

Brand Name Shanggui

Application Soldering, For Solar Panel

Material Copper wire coated by tin

The thickness of the tin layer 10μm-40μm, sided uniform

Specifications 1.6*0.18mm

Certificate TUV

Packging & Delivery

Min Order1 piece

Briefing

Detailed

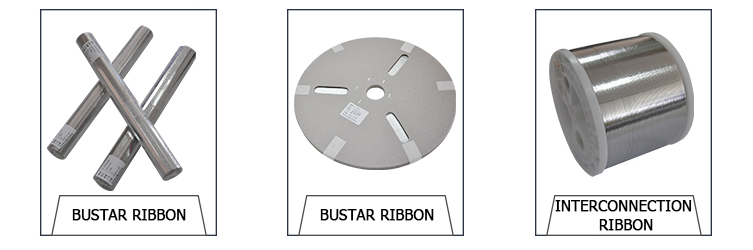

Solar Panel Materials Various Thickness Solder Wire bus bar

Our product is PV Ribbon (Interlinked belt, Lap welding Bus bar) ,which is an important component of solar panels.It can be used to interconnect solar cells and provides connectivity to the junction box.

Product Specifications:

| Product name | Specification (width*thickness) | Width tolerance | Thickness tolerance |

| interconnection ribbon | 0.9*0.27 | 0.01 | 0.005 |

| 1.0*0.27 | 0.01 | 0.005 | |

| 1.2*0.23 | 0.01 | 0.005 | |

| 1.2*0.25 | 0.01 | 0.005 | |

| 1.3*0.25 | 0.01 | 0.005 | |

| 1.6*0.16 | 0.01 | 0.005 | |

| 1.8*0.16 | 0.01 | 0.005 | |

| 1.8*0.18 | 0.01 | 0.005 | |

| busbar ribbon | 4.0*0.20 | 0.01 | 0.005 |

| 5.0*0.20 | 0.01 | 0.005 | |

| 5.0*0.35 | 0.01 | 0.005 | |

| 6.0*0.20 | 0.01 | 0.005 | |

| 6.0*0.25 | 0.01 | 0.005 | |

| 6.0*0.30 | 0.01 | 0.005 | |

| 6.0*0.35 | 0.01 | 0.005 | |

| 6.0*0.40 | 0.01 | 0.005 | |

| 8.0*0.25 | 0.01 | 0.005 |

Products technical features:

1. Options for raw materials (tin-coated photovoltaic ribbon of various thickness and width available as customers’ requirements)

GB/T11091-2005 standard Tul copper solder to be selected, copper contents ≥ 99.97%;

GB/T3952-2008 standard Tul copper solder to be selected;

GB/T8012-2008 standard tin-lead solder to be selected, beyond class A.

2. Volume resistivity of finished products : ≤0.0245 Ω. mm² /m(20℃)

3. Options for tin-coated photovoltaic ribbon coating alloy:

| Options | Compositions |

| Tin and lead system | Sn60% Pb40% |

| Sn63% Pb37% | |

| Sn62% Pb36% Ag2% | |

| Lend –free system | Sn100% |

| Sn96.5% Ag3.5% |

4. Tin thickness(mm): 0.01≤ single-side≤0.045(thickness can customized as customers’ requirements);

5. The yield strength≤65Mpa;

6. Tensile strength: ≥150Mpa;

7. Elongation : ≥20%;

8. Vickers hardness: ≤60(interconnections); ≤65(busbar);

9. Side camber(falciform bend):

As for discal packing products, not exceed 5mm for every 1000 long photovoltaic ribbon measured form its center;

You need a product

You May Like

- Nearest port for product export

- TIANJIN, SHANGHAI, SHENZHEN

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C