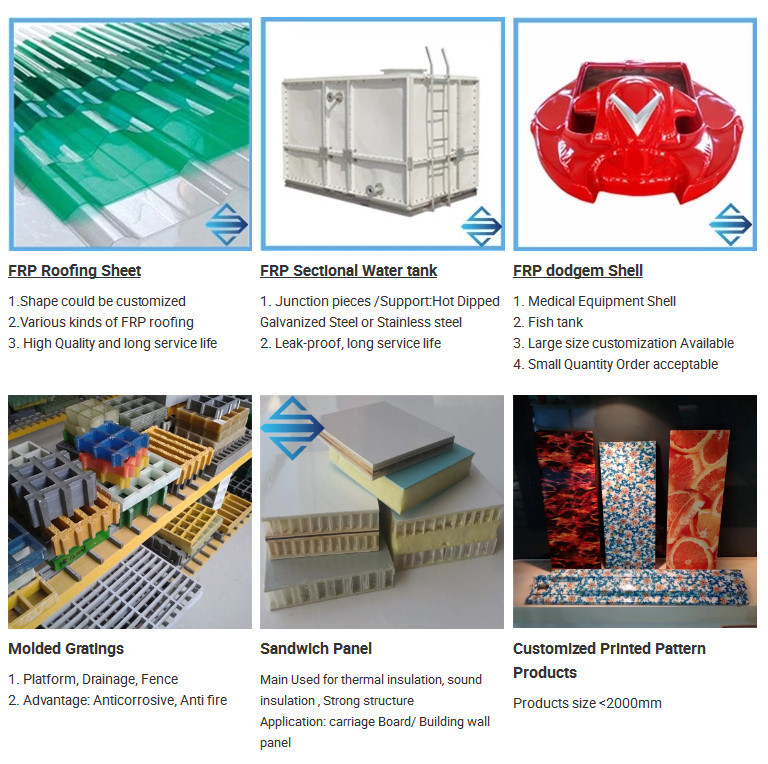

FRP Medical Equipment Cover Manufacturer

- US $6500.00

1 - 10 set

group nameFRP Medical Equipment Shell

-

Min Order1 set

brand nameSZ

modelCustomizable

payment methodL/C, D/A, D/P, Western Union, T/T, Paypal, Credit Card

-

update timeFri, 15 Jun 2018 12:37:14 GMT

Paramtents

Place of Origin Hebei, China (Mainland)

Brand Name SZ

Application Medical Equipment

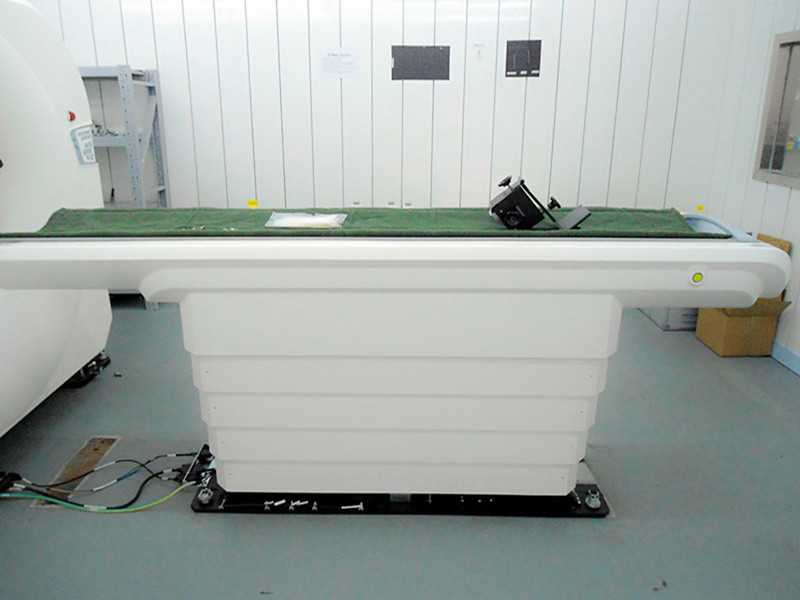

Surface Treatment Smooth

Technique Hand Lay-up

Material Fiberglass Reinforced Plastic

Feature Durable,Electric Non-conductivity Etc

Certificate ISO9001:2008

Dimensions Customizable

Packaging Details Carton and wooden case packing

Packging & Delivery

Min Order1 set

Briefing

high strength,light weight,anti-corrosion,installation fastness,preventing electric energy stealing,anti-rust,etc.

Detailed

You need a product

You May Like

- Nearest port for product export

- TIANJIN, QINHUANGDAO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, DDP, DDU

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union, Cash