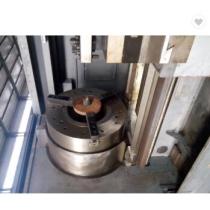

turning machine for pipe

group nameCNC Pipe Threading Lathe

-

Min Order1 piece

brand namesanzheng cnc lathe machine

modelQK1343

payment methodL/C, T/T

-

update timeThu, 26 Mar 2020 12:11:27 GMT

Paramtents

Dimension(L*W*H): 2570*1620*1940mm

guideway width: 755mm

hole through spindle: 440mm

Max length of workpiece: 1500mm/3000mm

max. swing over bed: 1000mm

Certification: CE&ISO

Packging & Delivery

Min Order1 piece

Briefing

Detailed

QK1343 CNC Pipe Threading Turning Lathe machine For Oil Country/automatic cnc pipe threading lathe machine for oil pipeline /CNC oil country lathe for large-size hole pipe fitting

CNC system

Standard CNC system:

Choose to configure the CNC system: Siemens, Fanuco,GSK

Tool holder form

Standard: 4-position electric turret

Select the configuration: 2/6/8/12 station electric knife holder

Chuck model

Standard: before and after the double three-jaw chuck

Select the configuration: before and after the double four-jaw chuck

Vertical four-position electric turret;With tailstock;Automatic lubrication system;Turning cooling system.Independent spindle, servo drives, variable speed.

Main Characters:

Hollow spindle bore design allows processing extra-long work-piece

Double chuck equipment realizing better clamping of work-piece

Taper guide bar installed ensures taper thread processing ability

E-mail:alice..........com

WhatsApp:86-155-6681-6110

You need a product

You May Like

- Nearest port for product export

- Dalian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C