oil country pipe thread cnc lathe

group nameCNC Pipe Threading Lathe

-

Min Order1 piece

brand namesanzheng cnc lathe machine

modelQK1352

payment methodL/C, T/T

-

update timeThu, 26 Mar 2020 11:48:06 GMT

Paramtents

oil country pipe thread lathe Power(W): 30KW steel pipe threading cnc lathe

turning machine for pipe guideway width: 755mm threading cnc lathe

pipe processing equipment hole through spindle: 520mm pipe thread cutting cnc machine

pipe thread cutting lathe Machine Type: Horizontal CNC Lathe

pipe thread lathe Max. Swing Diameter: 1250MM pipe thread cutting machine

pipe thread lathe CNC Dimension(L*W*H): 6250*2800*2600mm

pipe threading cnc lathe max. swing over bed: 1250mm pipe threading lathe machine price

pipe threading lathe Voltage: 380 3phase 50hz

lathe pipe threads Weight: 165000k

max. swing over carriage: 610mm

Packging & Delivery

Min Order1 piece

Briefing

Detailed

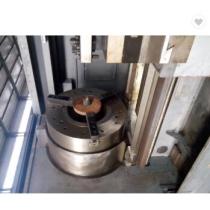

The digitally-control pipe threading lathe,a special tool to turn and mill pipe threads,characterized by larger diameter of the spindle bore(over 130mm in general) and chucks installed before and behind the head stock so as to hold and process tubular or rod pieces of latge diameters. In addition to milling cylindrical/conical SI/BS pipe threads,it can be used to replace the general lathes to mill outer diameters,bore holes,and planes.It is widely used to process working pieces such as drilling pipes/collars and casing in the sectors such as petroleum,smelting,chemistry,hydropower and geologic exploration.

CNC pipe thread lathe is a special machine tool for pipe thread turning machining. Its feature is that the spindle bore is relatively large (usually 130 mm or more), and the spindle box has chucks before and after, in order to facilitate the clamping and processing of large-diameter pipes and rods. Can turn metric, imperial cylindrical, tapered pipe thread, can also be used to replace outer lathes, boring holes, internal and external taper surfaces, and planes, etc. in lathes. The lathes are widely used in the petroleum sector, the gold manufacturing department, chemical industry, hydropower, and geological exploration. Other departments deal with the machining of drill pipes, drill boats, and casings.

QK series CNC Pipe threading lathe machine is mainly designed to process all kinds of internal and external pipe threads including metric,inch,module,DP and taper threads,as well as having all the common functions of normal CNC lathe such as processing the inner bore and end face of shafts and disks.

This series lathe machine is widely used in industries including petroleum exploiting,coal and minerals mining,chemical piping and geological prospecting,it is high-efficiency equipment in processing and repairing drilling pipe,drilling rod,thread coupling and so on.

E-mail:alice..........com

WhatsApp:86-155-6681-6110

metal cutting and pipe threading cnc lathe machine equipment

You need a product

You May Like

- Nearest port for product export

- Dalian, Ningbo, Shanghai, Tianjing

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C