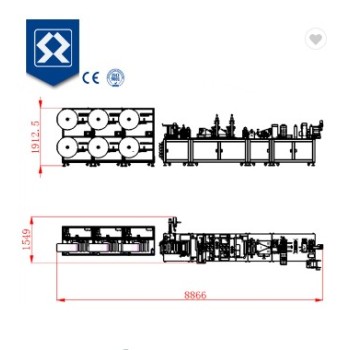

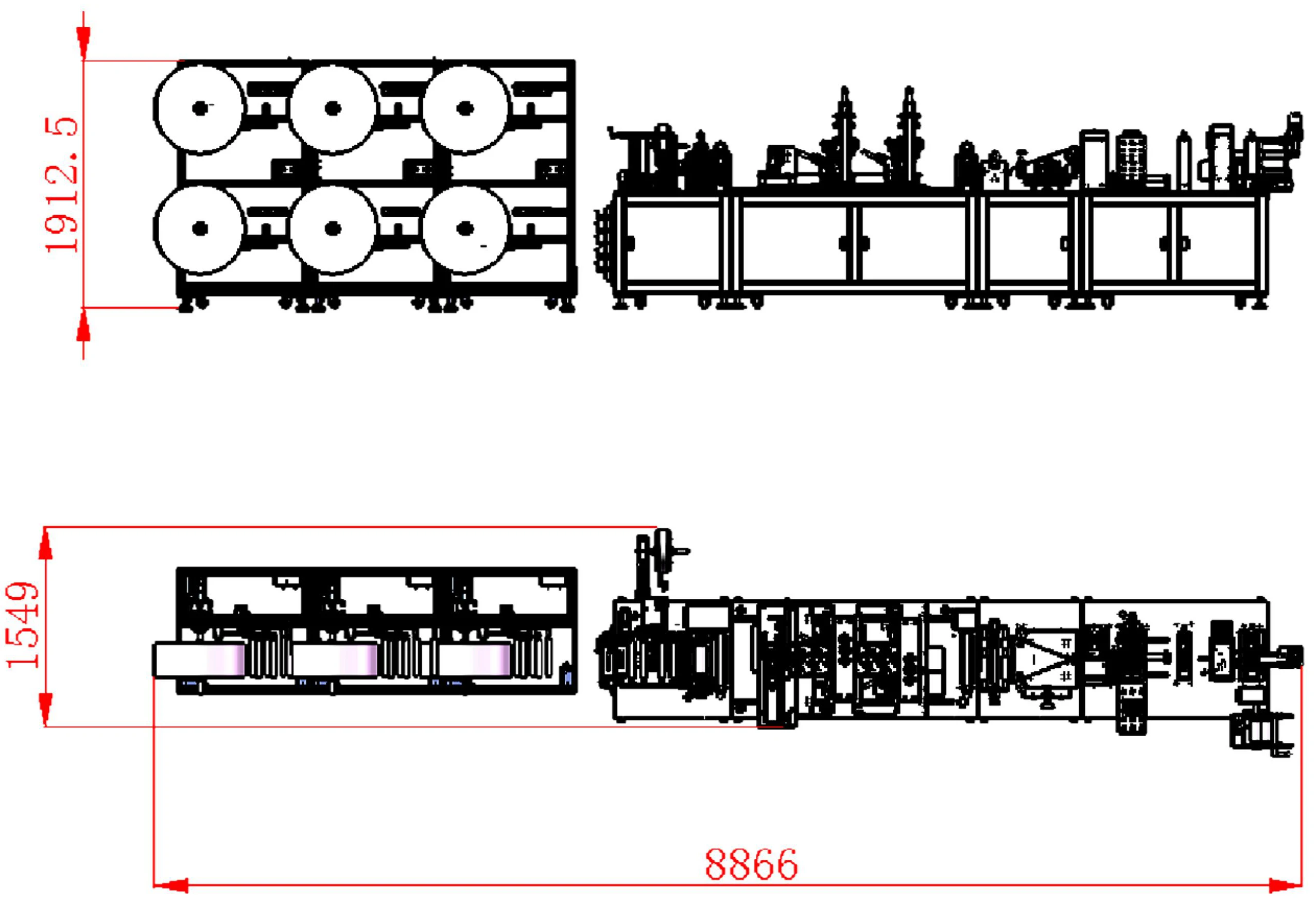

Equipment overview and compositionThis equipment is a fully automatic production line for N95 series folding masks, which can realize the N95 masks from the raw material cloth roll feed, nose line welding, mask surface welding, automatic body cutting, logo printing, valve hole punching cutting (optional), breathing valve installation (optional), body cutting, earloop Fully automated production from welding, main body forming, main body fusing to blanking of finished products. The equipment will not cause any damage to the filtering performance of raw materials during operation. The filtering effect of N95 masks produced by this equipment can pass the international N95 standard test.The device is mainly composed of the following parts:a. Non-woven fabric roll placement and tension control unit (a total of 6 roll placement devices).b. Automatic cloth deviation correction unit (this is optional).c. Non-woven composite rolling unit:Composed of a rubber roller and a steel roller, the roller pressure can be adjusted by adjusting the spring tension.d. Mask nose clip assembly unit:Including automatic feeding, leveling, cutting, conveying, assembly and ultrasonic welding of coils, the length of the nose clip can be adjusted within the set rangee. Mask surface pattern welding unit:The pattern adopts ultrasonic welding. The ultrasonic welding system is equipped with a cooling system. The pressure of the welding system is adjustable. The ultrasonic working program is controlled by a PLC connected to the host. The main technical parameters of the ultrasonic welding system are: power 2.0KW, frequency 20KHz. Welding or knurling wheels of the system can be operated on the touch screen. It can be opened or locked by controlling the opening and closing of the cylinder, and the compression gap can be adjusted.f. Character printing unit (this item is optional):Equipped with Marken 5200 series dual print head printer (optional), the print head position can be adjusted by adjusting the structure.g. Ear strap assembly unit:Straighten and straighten the earloop by applying a certain tension to the earloop. The length tolerance of the earloop is XX + 1-2.5mm (depending on the customer's drawing). The cut of the earloop is cut flat and there is no fiber left. The ultrasonic welding process is used to achieve the connection with the mask body. The knitted belt is completely welded, no defects such as desoldering, over-welding, and virtual welding. The tensile force after welding is greater than 16N.h. Body cutting and waste discharging unit:According to the designed cutting contour, the body is cut with a group of rolling cutter wheels (the cutter material is made of speed steel), and the pressure of the 10,000 pad wheels is adjustable.i. Breath valve assembly unit (this unit is an optional unit, the unit is not included in the standard configuration):The valve body parts are automatically fed by the vibrating disc, and the batching bin of the vibrating disc has a feedinginterval of more than 1 hour. After the valve body is assembled to the body, the ultrasonic welding process is used for welding. The power of the welding system is 2.0KW, the frequency is 20KHz, and the pressure of the welding system is adjustable.j. Folding forming unit:The position of the molding triangle plate can be adjusted by the adjustment mechanism (up and down, left and right adjustable range is +/- 2mm).k. Nose and forehead welding unit:Welding using ultrasonic welding process, the pressure of the welding system is adjustable.l. Forming and cutting unit:It consists of a rolling cutting wheel and a shim wheel, with adjustable pressure. The cutting material is high-speed steel.m. waste separation unit.n. Control system: Mitsubishi PLC control system in Japan and Taiwan Weinviewtouch screen operating system.

E-mail:alice..........com

WhatsApp:86-155-6681-6110

Function Description

1. Non-woven fabric coil placed and tension control unit (total 6 group of coil placed device)2. Nose clip welding automatically3. The face mask is embossed and fused4. LOGO printing5.Left earloop welding6. Right earloop welding7. Mask folding and welding8. Mask bod cutting9. Mask finished products unloading10. Waste materials discharge

Auto Blank Face Mask Making Machine Machine Parts Spec:

The finished size of the mask shall refer to the process drawings or samples provided by the customer, and the equipment accessories with directly different product specifications such as ultrasonic welding head, hob and cutting knife shall refer to the above process drawings or samples provided by the customer.