CE certificate customized crimping roll forming machines manuafaturer with ISO quality system | ZHONGYUAN

group nameMetal Sheet Roll Forming Machines

-

Min Order1 piece

brand nameZHONGYUAN

-

update timeTue, 21 Apr 2020 18:58:18 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Crimping forming machine

| Technical data of Crimping forming machine | |

|---|---|

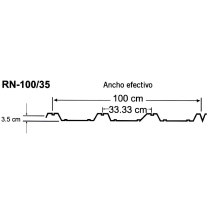

| Raw material | corrugated steel sheet (235-345Mpa) |

| Material of roller | 45# steel being quenched treatment |

| Material of crimping device | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Crimping speed | about 10times /minute |

| Power Requirement | Main motor power: 2.2Kw(Depend on final design) |

| Hydraulic station power: 5.5Kw (Depend on final design) | |

| Diameter of shaft for rollers | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of feeding rollers | about 3 stations for main rollers |

| Weight of machine | About 3000KGS |

| Size of machine | about 1600mm×1600mm×1750mm |

Product application of Crimping forming machine

The product from the roll forming machines is used as roof of building.