PET Preform Mold

group namePET Preform Mould

-

Min Order1 piece

brand nameSenio

payment methodMoneyGram, T/T

-

update timeWed, 24 Oct 2018 14:38:15 GMT

Paramtents

Product name Plastic Pipe Fitting Mold

Material PP

Application Sewerage

Diameter 110mm 50mm 75mm

Steel P20 HRC28-32

Mould Base Material S45C

Slider S45C

Flaring head steel H13 HRC 48-52

Runner Cold runner submarine gate

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Plastic Pipe Fitting Mold

MOULD INFO

Product name Plastic Pipe Fitting Mold Steel P20 HRC28-32 Plastic material PP Application Sewerage Dimension 110mm 50mm 75mm Mould Base Material S45C Runner Cold runner submarine gate

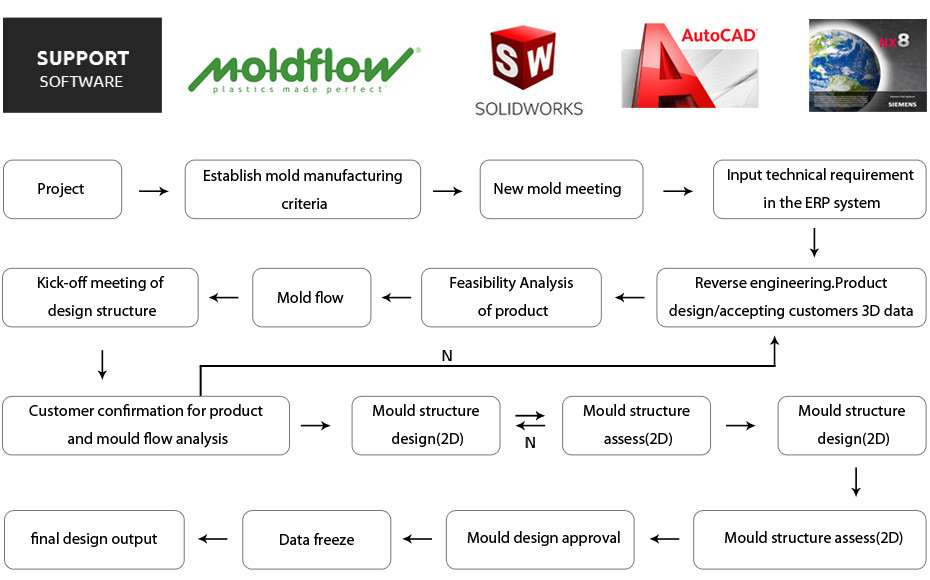

Mold processing advantages

New advanced needle valve gate system.

Each cavity is self-lock independently to ensure low decent ration of product.

Low decent ration of product

The excellent hot runner design assures uniform heating and greatly improves the quality of plastic products.

style

Plastic pipe fitting style

Production process

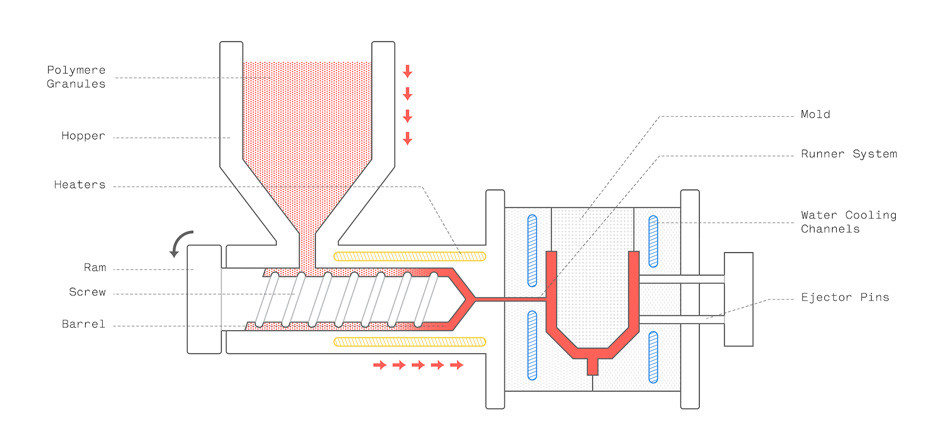

The mold is a split metal block (usually steel or stainless steel) that is machined to form the cavities in the block. Hollows in the mold parts are created by tools shaping the part cavity. The molded parts are created by filling the cavity in the mold through a filling port called gate. Depending on the part to be made, an injection mold can be made with multiple cavities and integrated by several gates.

1st reportJuly 14th 2017

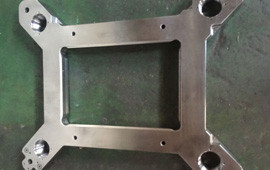

Engraving for sliders

Mold frame finished

Template finished

2nd reportJuly 21st2017

Engraving for sliders

This part is the biggest processing capacity during the whole mold processing.

Sliders engraving finished

Stripper plate finished

3rd reportJuly 28th 2017

Processing finished,Next step, assemble

Processing finished,Next step, assemble

Processing finished,Next step, assemble

How does Injection Molding work?

Production process

Put BMC or injection SMC into the stuffing device of the injection device feed. These thermosetting materials require a reverse check valve. The composite material is then injected into the closed mold, filled with cavity and polymerized. After fully solidified, the hot product is removed from the mold.

Injection molding is used for machining high precision parts and complex parts.

SMC/BMC/DMC mould

The basic properties of sheet molded plastics and ball molded plastics are thermosetting, which means that the cross-linked materials are irreversible in crosslinking. This is also the basis for forming these material types and unique mold technology.

The material is made up of the following components:

| SMC/BMC/DMC composite: | Resin, low shrinkage agent, filler, strengthening agent, additive, curing system; |

| SMC/BMC molding: | Molding is done on a heated steel mold with a temperature of 125 degrees C-170 degrees C. |

Q: What size range of moulds can you make?

A: The mould can be up to 4 meters in length, 2.8 in width and 40 tons in weight.

Q: Do you make hot runner moulds?

A: Yes, we are skilled at using various hot runners such as D-M-E, YUDO, Mold-master, Synventive, husky, PSG, HASCO, etc. For the mould you want to machine, you can choose the hot runner system that you are satisfied with.

Q: What file formats can you receive?

A: We can accept different file formats such as IGES, DXF, DWG, STP, PRT, X_T, PDF, etc.

Q: What are the plastic materials you use?

A:ABS, PP, PC, PE, HDPE, POM, PA6, PA66, PA6+GF, PS, PMMA, TPU, TPE, PVC, etc. We have extensive experience in the injection molding process of these materials, and adjust the injection parameters to get the perfect plastic products.

Q: How is the mould packaged and shipped?

A: When the mould is finished, we will apply a layer of anti-rust paint on the surface, then wrap it in plastic film, wrap it and put it into a sterilized wooden box.

Additional Documents: 1.A1 paper size assembly drawing; 2. electrode description; 3. lifting ring, screw description; 4. material proof; 5. mold brake device and other necessary accessories.

Q: Do you sign a confidentiality agreement?

A: Yes. We understand the importance of design to you. Signing a confidentiality agreement is also our company's policy. We may not disclose or copy any design or ideas about your company's products or your company's information to third parties without your permission.

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NIGNGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Westem Union, Cash