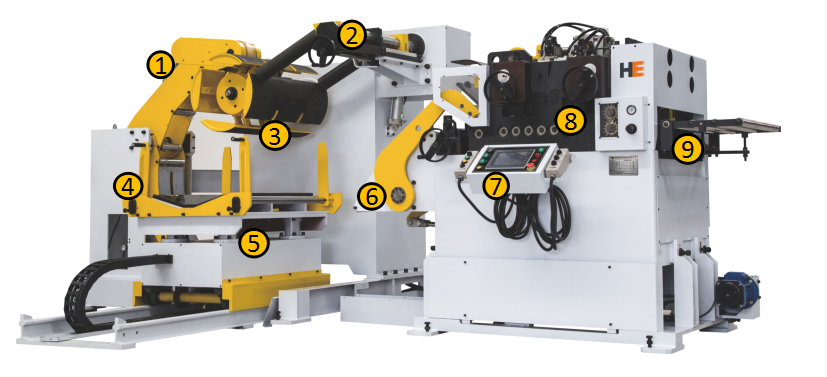

GLK4 Automation Feeding System In Press Room For Brake Pads Bracket Auto Parts Punching

group nameGLK4 3 in 1 Coil Feeder for Press

-

Min Order1 piece

brand nameHongEr

modelGLK4

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeTue, 02 Jul 2019 14:32:55 GMT

Paramtents

Function automatic feeding compact press

Feature with coil car loading metal sheet

Name decoiler straightener auto feeding

Compact pressing machine

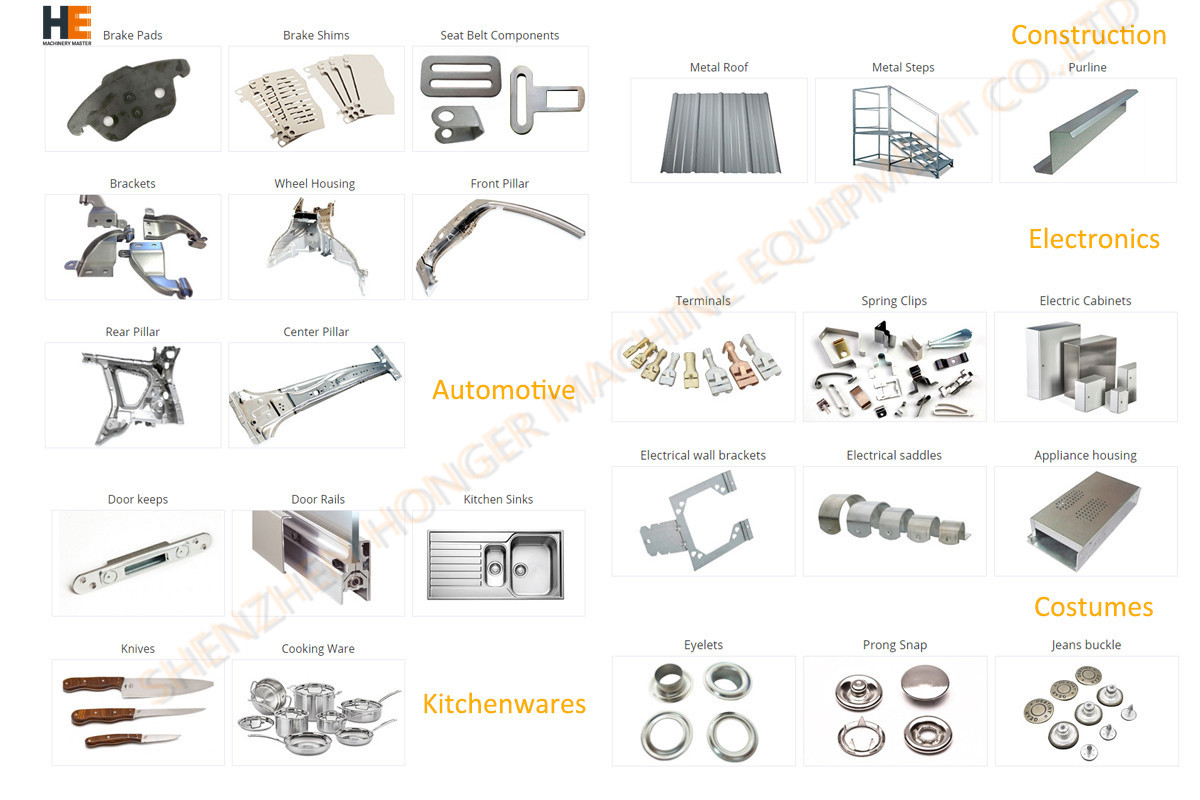

Usage auto metal parts stamping

attribute 3 in 1 servo feeder machine

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Model |

GLK4-400 | GLK4-500 | GLK4-600 | GLK4-800 |

GLK4-1000 |

GLK4-1300 |

Material | Hot Rolled Steel, Cold Rolled Steel, Galvanized Steel, Painted Steel, Stainless Steel, Copper, Aluminum etc. | |||||

Coil width(mm) |

70-400mm | 70-500mm | 70-600mm | 70-800mm |

70-1000mm |

70-1300mm |

Coil thickness | 0.6-6.0mm | |||||

Coil weight | 5000kg | 5000kg | 5000kg | 7000kg | 7000kg | 10000kg |

Coil I.D.(mm) |

480-520mm |

|||||

Coil O.D.(mm) |

1500mm |

|||||

Max. speed | 16-24 m/min | |||||

Feeding accuracy | +/- 0.15 mm | |||||

Straightener rollers | 4 rollers on top 3 rollers on bottom | |||||

Power | 380V 60HZ | |||||

Expansion | Hydraulic | |||||

Pressing arm | Pneumatic Type | |||||

Servo motor | AC5.5 | AC5.5 | AC7.5 | AC7.5 | AC11 | AC11 |

Uncoiler motor | AC2.2 | AC2.2 | AC2.2 | AC3.7 | AC3.7 | AC7.5 |

You need a product

You May Like

- Nearest port for product export

- Shenzhen Port, Jieyang Port, Shanghai Port, Tianjing Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow