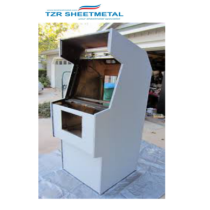

Metal fabrication and assembly of a consumer banking component

group nameSheetmetal Fabrication

-

Min Order2 piece

brand nameTZR

payment methodWestern Union, T/T, Paypal

-

update timeWed, 13 Mar 2019 09:46:47 GMT

Packging & Delivery

Min Order2 piece

Briefing

Detailed

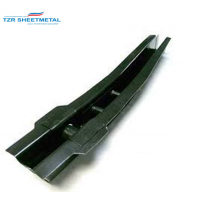

Project Description | Consumer banking component |

Capabilities Applied/Processes | Primary:Metal fabrication Secondary: Assembly |

Equipment Used to manufacture part | Laser,Turret Punch,Press brake,Hardware insertion,Spot welding,Weld grind&polish,Mechanical brush |

Standards Met | Customer Requirements |

Tightest Tolerances | ±.005” |

Material used | Cold Rolled Steel,Aluminum galvanized |

Material finish | ZUNC&Clear plate,Paint,Anodize |

Industry for use | Banking |

In process testing/Inspection performed | Laser scan flat blanks,All piece parts first article inspection,Final inspection upon completion |

At TZR Sheetmetal company our6 years of experience gives us the ingenuity to uncover the most successfulmethods for fabricating sheet metal assemblies. The complex componenthighlighted here is used in a consumer banking application. Based on the finalpart requirements, our designers weighed out all the options and developed asmart fabrication strategy that simplified manufacturing, improved quality, andreduced the overall production costs.

Withour comprehensive fabrication and inspection capabilities, we designed andbuilt this workpiece entirely in-house. Constructed from cold rolled steel andgalvanized aluminum parts, it consisted of 50 individual components combinedinto several sub-assemblies that make up the final put-together unit. Ourintegrated sheet metal production systems allowed us to operate with accuracyand efficiency while maximizing material utilization and minimizing productionand assembly steps.

Productioninvolved many of our fabrication capabilities, including laser cutting,bending, and punching. Some of the pieces we connected by spot welding whileother parts of the assembly required hardware insertion. All of the spot weldswere ground and polished to give a seamless appearance. We also applied variousfinishes, including zinc plating, anodizing, and painting.

You need a product

You May Like

- Nearest port for product export

- ShenZhen

- Delivery clauses under the trade mode

- FOB, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, PayPal, Westem Union