OEM Custom Percision CNC Machining Aluminum/Brass/SUS304 Hydraulic Manifold Manufacturer

group nameCNC Part

-

Min Order1 piece

brand nameTZR

payment methodWestern Union, T/T, Paypal

-

update timeWed, 08 May 2019 19:21:42 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Application:

Typical applications include machine tools, production and material handling equipment, food processing, marine, off-highway equipment, heavy construction equipment, oil field and farm equipment, and valve operations.

Function:

Industries Served for Manifolds manufacturing Agriculture Automation Dental Entertainment / Recreation Food & Beverage Material & Fluid Handling Medical Oil & Gas / Energy Packaging Printing Semiconductor Testing & Measurement Transportation.

Operation:

1. An electric hydraulic manifold assembly includes:

(a) a manifold body (12), which has an inlet passage connected with multiple valve chambers (42-50, 102, 104), each valve chamber has a separate outlet passage (56-66, 110) and a pressure induction outlet (134-142) connected with each outlet passage;

(b) an electric valve (16-26, 28, 30) which is arranged to control the inlet passage and the outlet passage. The pressure in the valve chambers between the separated outlet channels;

(c) a lead frame (14) with multiple sets of electrical terminals (200-224) arranged on the manifold body is electrically connected with one of the valves. The lead frame comprises a plurality of pressure sensors (32-40), on which the pressure sensors are positioned, respectively, with the pressure sensing ports. One is connected;

(d) a device (252 to 256) that acts as a fixing device for the lead frame on the manifold body.

Feature:

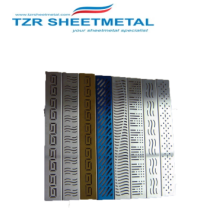

▲Steel, aluminum, cast or ductile iron manifold blocks.

▲Anodized or zinc plating for protection in severe environments.

▲Industry-common valve cavities.

▲Fittings, CETOP valves and accessory components can be included.

▲"FastTrak" service for quick delivery of a working prototype.

Tips:

1. Fluid type

2. Seal materials

3. Material and finish

4. Environmental conditions and temperatures

5. Pressure (maximum and working)

6. Duty cycle

7. Flow conditions (pump, accumulator and return)

8. Port sizes, types, and locations

9. Number of and type of valves

10. Electrical voltage and connection

11. Mounting

Technical specification:

• 0.7 A max at 24 VDC or 1.2 A at 12 VDC each function

• 100Hz response per valve

• Electronics tested to 3500 meters (11480 ft)

• Choice of electrical connectors

You need a product

You May Like

- Nearest port for product export

- ShenZhen

- Delivery clauses under the trade mode

- FOB, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, PayPal, Westem Union