Manual Powder Coating Paint Machine, Industrial Powder Coating Machines for Metal-PaintGo 660

group namePower Coating Machine/Powder Spraying System

-

Min Order1 piece

brand nameACMAN

modelPaintGo-660

payment methodT/T, PayPal, Westem Union

-

update timeFri, 21 Oct 2022 12:19:14 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

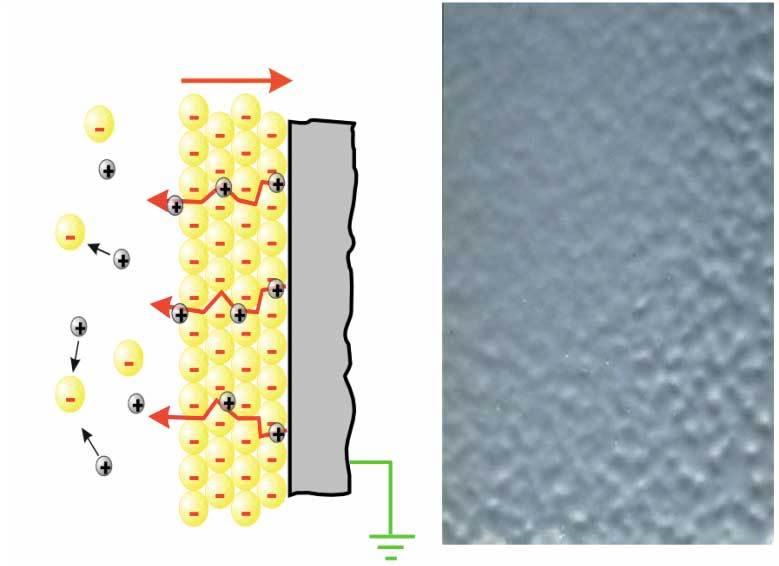

Benefits: Faster Coating Speed, High Productivity

Benefits: Making more powder with ions, save powder materials.

3: Advanced Controller:

Benefits: Precise Powder Output, Increasing utilization rate of raw power.

4: Multi-choices Nozzle: Super Cascade

Benefits: Ensuring perfect powder atomization, Improving surface quality.

5: Cleaning Mode:

Benefits: Fast color change, Non-stick material

2:Visual control panels: the voltage, current, conveying air pressure, supplementary air pressure, rinsing air pressure.

Benefits:

1: Faster Coating Speed, High Productivity;

4: Improved surface quality;

6: Safety: Safe manual operation;

7: Maximum operation performance.

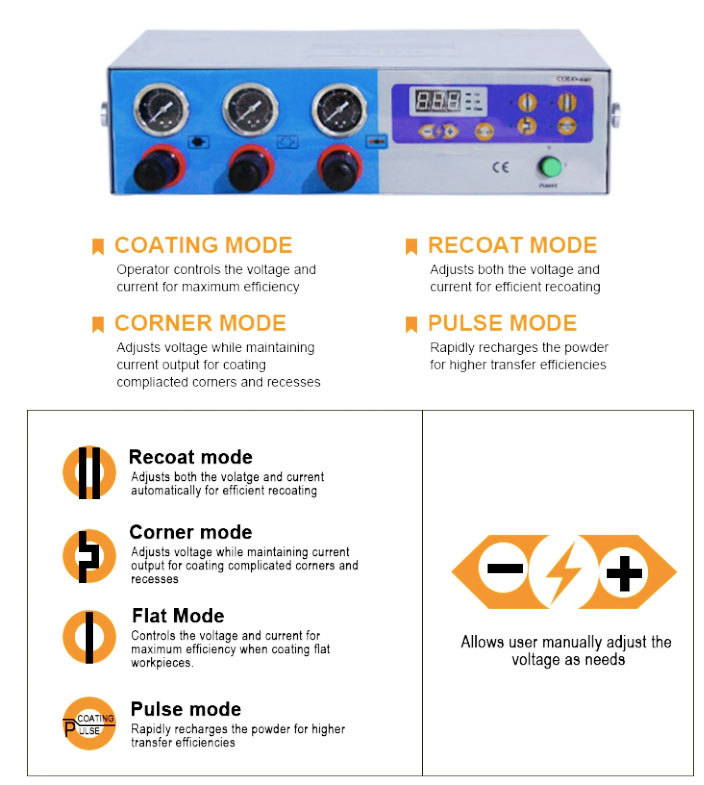

The difference between PaintGo660 and PaintGo 500 is that the 660 add a pulse mode and four pre-programmed options for processing:

Pulse mode could let the gun add more electric charge which will sharply promote the utilization rate of powder, save cost.

1: Re-coat Mode: Voltage and Current Pre-programmed suiting for recoating process;

2: Corner Mode: Voltage and Current Pre-programmed suiting for corner workpiece;

3: Flat Mode: Voltage and Current Pre-programmed suiting for flat workpiece;

4: Pulse Mode: Rapidly recharge the powder when change the powders;

1: Making more powder with ions, save powder materials.

4: Quick-release coupling for the powder hose makes the powder change easier and quicker.

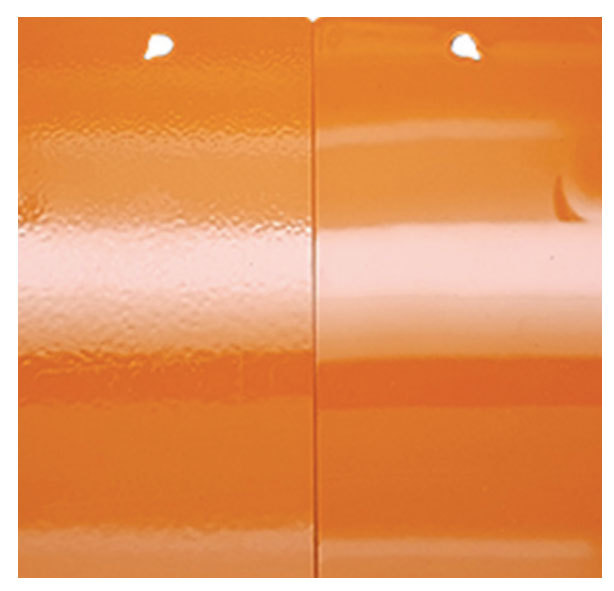

the Left one is the orange peel coating

Many things can cause orange peel defects. Here’s a list of common possible caused and what you can try to fix them:

PaintGo-660 Powder Coating Machine | |||

|

Mains input voltage

|

220V

|

Operating frequency

|

50Hz/60Hz

|

|

Powder

|

50W

|

Output voltage(to the gun)

|

0-100KV(adjustable)

|

|

Maximum output current(to the gun)

|

180UA(max)

|

IP Index

|

IP54

|

|

Pneumatical data input pressure |

Min6bar(87PSl)/max.10 bar(145PSI)

|

Recommended input pressure

|

7 bar (1015PSI)

|

Max.Water vapor content of the compressed Air | 1.4g/m3 | Max.Oil vapor content of the compressed air | 0.1mg/m3 |

Max Air Consumption | 13.2 N m3/H | T Pulse | 15-20Clock/Sec |

Max Powder Injection | 600g/min | Polarity | Negative |

The vibration type do not need powder bin, the suction pipe could suck the powder directly from the original powder bags.

So, It is suitable for multi-colors changing processes, which could save changing time.

The disadvantage is that there is a little bit noise for the vibration.

You need a product

You May Like

6YRS ACMAN ENVIRONMENT (HANGZHOU) CO.,LTD

- Nearest port for product export

- Shanghai Port, Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, PayPal, Westem Union