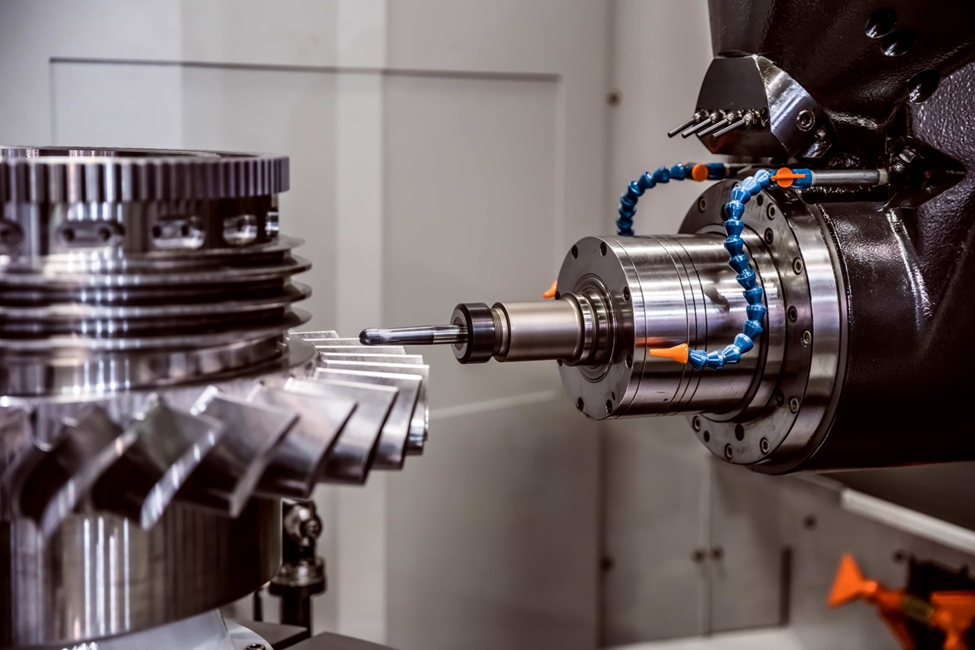

High Precision Customized Brass CNC Machininig Parts Motor Shaft Sleeve Coupler for Auto Parts

- US $5.00

1 - 100 piece

- US $4.00

101 - 1000 piece

- US $3.00

1001 - 10000 piece

group nameCNC Machining Parts

-

Min Order1 piece

brand nameZehan CNC Machining Parts Service

modelOEM

payment methodL/C, D/A, D/P, Western Union

-

update timeThu, 16 Jan 2020 19:16:29 GMT

Paramtents

Material steel,brass,aluminum,stainless steel

Process CNC machining,Turning,Milling,Hot forging,Cold heading

Requirements No burr,Scratches,Dents,Pits,Oil stain

Package Bulk packing , Cartons, Pallets, Wooden case

MOQ 50 pcs

FOB Port Qingdao

Lead time 15-20 days.

Shipping by sea, by air, by DHL, UPS, Fedex , TNT & etc.

Main Export Markets USA, Canada ,Britain , Belgium , Germany, Mexico, Netherlands, Japan , The United Arab Emirates

Payment method T/T, PayPal , Western Union

Packging & Delivery

Size31cm x21cm x17cm

Weight1kg / piece

Min Order1 piece

Briefing

Detailed

|

Product Name

|

High Precision Customized Brass CNC Machininig Parts Motor Shaft Sleeve Coupler for Auto Parts |

||

|

Quality Assurance

|

We promise 100% inspection before shipping

|

||

|

Material

|

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

|

||

|

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc.

|

|||

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on. | ||

Inspection Tools | Projector etc. | ||

File Format | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||

Machining Equipments | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, Credit Card, PayPal, Westem Union