light metal structure workshop

group nameSteel Structure Buildings

-

Min Order500 square meter

brand nameZYM steel structure building Manufacturer

modelZYM1

payment methodL/C, D/A, Western Union, T/T

-

update timeWed, 27 Dec 2023 21:35:42 GMT

Paramtents

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

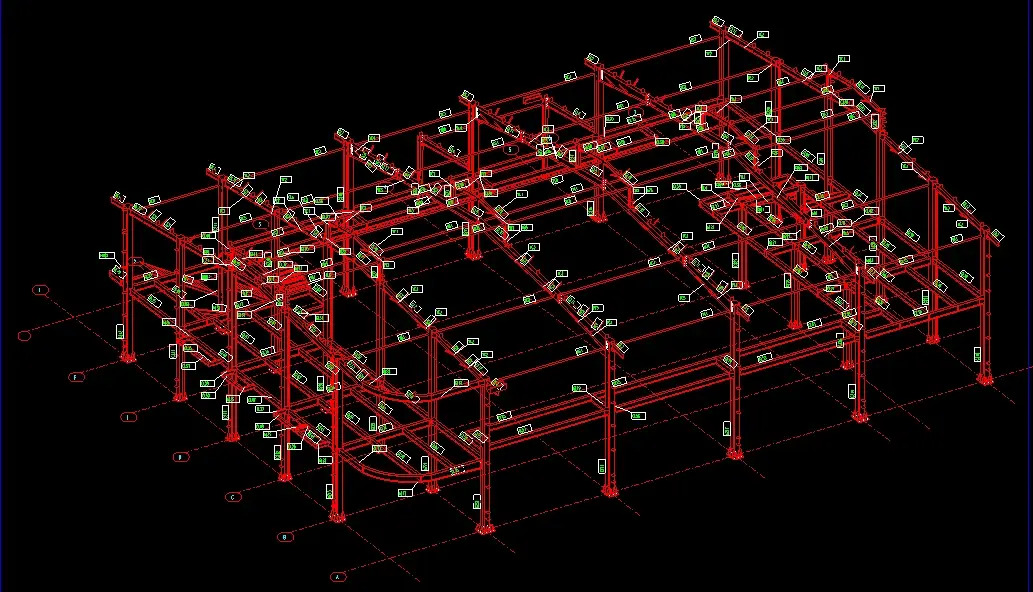

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

Min Order500 square meter

Briefing

Detailed

ZhengYuanming Construction Engineering Co., Ltd.. is a large scale professional steel structure company integrates the designing, production and installation. With a total building area of 10,000 square meters, our company boasts much domestically advanced equipment, such as two steel structure automatic welding lines, two color steel molding lines, production lines for the C-section and Z-section steel purline, and various production equipment for automatic cut and welding. The annual capacity of processing and manufacture is about 40,000 metric tons. Our company has the second-level qualification for professional steel structure contracting. The company currently has 260 employees, including 65 senior and intermediate engineering and technical personnel. The company's main business areas and products are as follows: 1. All kinds of Georgia, production and installation. Factories, warehouses, high-rise buildings2. Steel structure and welded H-beam raw material processing and distribution3.our products have entered into many foreign countries like the Iraq

| Product name |

light metal structure workshop |

|---|---|

| Brand Name |

ZYM |

| Material |

bolt,Pressure plate etc |

| Brand |

ZYM light metal structure workshop Manufacturer |

| Keyword |

small size steel structure warehouse,economic steel structure warehouse,prefabricated modern design steel structure workshop,Prefab Steel Structure Warehouse Shed,light steel structure warehouse building cos |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| OEM&ODM |

YES |

| Application |

prefab fabricator steel structure warehouse,steel structure warehouse storage,single span steel structure warehouse,engineering steel structure warehouse,Industry Steel Structure Warehouse |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Malta,Israel,Honduras,Malaysia,Switzerland,Swaziland |

ZYM After-Sale Service , we will still provide the service after the light metal structure workshop installation.

specially used for steel structure factory, color steel plate V840 and 950 color steel plate for warehouse

We always do free steel structure warehouse building design for clients with CAD and 3D max.light metal structure workshoplight metal structure workshop services FAQs GuideAre you looking for a quick review guide about light metal structure workshopservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding light metal structure workshop services.Let’s continue!

2.What are the advantages of prefabricated light metal structure workshop?

3.What are the fire safety standards for light metal structure workshop?

4.What is the maximum height that can be achieved with a ?

5.What are the most common applications for light metal structure workshop?

6.What design options are available for the exterior aesthetics of a light metal structure workshop?

7.What is the process for constructing a steel structure building?

8.Are there any limitations on the design possibilities for light metal structure workshop?

9.light metal structure workshop What is the average lifespan of a steel structure building?

10.What is Steel Structure and How Does it Differ from Traditional Construction?

11.What certifications do your products have?

12.What is the insulation and energy efficiency of light metal structure workshop?

13.Are there different types of steel used in the construction of light metal structure workshop?

14.What are the design considerations for a light metal structure workshop?

1.Are light metal structure workshop environmentally friendly?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers. Yes, steel structure buildings are environmentally friendly. Steel is a recyclable material, so steel structure buildings can be disassembled and the steel reused. Steel is also a durable material, so steel structure buildings can last for decades with minimal maintenance. Steel structure buildings also require less energy to construct than other types of buildings, making them more energy efficient.

2.What are the advantages of prefabricated light metal structure workshop?

We continue to invest in research and development and continue to launch innovative products. 1. Cost-Effective: Prefabricated steel structures are cost-effective and can be built quickly, saving time and money. 2. Durability: Steel is a strong and durable material that can withstand harsh weather conditions and is resistant to fire, termites, and other pests. 3. Flexibility: Prefabricated steel structures can be easily modified and adapted to fit any design or purpose. 4. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction. 5. Low Maintenance: Steel structures require minimal maintenance and are easy to clean and repair. 6. Versatility: Prefabricated steel structures can be used for a variety of applications, from residential to commercial and industrial.

3.What are the fire safety standards for light metal structure workshop?

Our light metal structure workshop products have competitive and differentiated advantages, and actively promote digital transformation and innovation. 1. Steel structures must be designed and constructed in accordance with the applicable building codes and standards. 2. Fire-resistant materials must be used in the construction of steel structures. 3. Fire-resistant coatings must be applied to steel structures to protect them from fire. 4. Fire-resistant insulation must be installed in steel structures to reduce the spread of fire. 5. Fire-resistant doors and windows must be installed in steel structures to prevent the spread of fire. 6. Fire-resistant sprinkler systems must be installed in steel structures to control the spread of fire. 7. Fire-resistant smoke detectors must be installed in steel structures to detect the presence of smoke. 8. Fire-resistant fire extinguishers must be installed in steel structures to extinguish fires.

4.What is the maximum height that can be achieved with a ?

We focus on providing high light metal structure workshop quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

5.What are the most common applications for light metal structure workshop?

We have a good reputation and image in the industry. The quality and price advantage of light metal structure workshop products is an important factor in our hard overseas market. 1. Warehouses 2. Industrial Buildings 3. Agricultural Buildings 4. Retail Stores 5. Offices 6. Aircraft Hangars 7. Churches 8. Garages 9. Sports Facilities 10. Carports

6.What design options are available for the exterior aesthetics of a light metal structure workshop?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced light metal structure workshop products. 1. Paint: Steel structures can be painted in a variety of colors to match the surrounding environment. 2. Siding: Steel structures can be clad in a variety of siding materials such as brick, stone, stucco, wood, or metal. 3. Windows and Doors: Steel structures can be fitted with a variety of windows and doors to match the desired aesthetic. 4. Roofing: Steel structures can be fitted with a variety of roofing materials such as metal, shingles, or tiles. 5. Lighting: Steel structures can be fitted with a variety of lighting fixtures to enhance the exterior aesthetic. 6. Awnings: Steel structures can be fitted with awnings to provide shade and protection from the elements.

7.What is the process for constructing a steel structure building?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Design: The first step in constructing a steel structure building is to design the building. This includes determining the size, shape, and layout of the building, as well as the type of steel to be used. 2. Fabrication: Once the design is complete, the steel components must be fabricated. This includes cutting, bending, and welding the steel into the desired shapes and sizes. 3. Erection: Once the steel components are fabricated, they must be erected on the building site. This includes assembling the steel components and connecting them to the foundation. 4. Finishing: The final step in constructing a steel structure building is to finish the building. This includes adding insulation, drywall, and other finishing touches.

8.Are there any limitations on the design possibilities for light metal structure workshop?

We pay attention to user experience and product quality, and provide the best product quality and lowest production cost for cooperative customers. Yes, there are several limitations on the design possibilities for steel structure buildings. These include the availability of steel, the cost of steel, the weight of the steel, the strength of the steel, the size of the steel, the shape of the steel, the welding techniques used, and the fire resistance of the steel. Additionally, local building codes and regulations may also limit the design possibilities for steel structure buildings.

9.light metal structure workshop What is the average lifespan of a steel structure building?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The average lifespan of a steel structure building is between 50 and 100 years, depending on the quality of the materials used and the maintenance of the building.

10.What is Steel Structure and How Does it Differ from Traditional Construction?

We should perform well in market competition, and the prices of light metal structure workshop products have a great competitive advantage. Steel structure is a type of construction that uses steel as the primary structural element. It is typically used for large buildings and bridges, and is becoming increasingly popular for residential and commercial construction. Steel structure differs from traditional construction in that it uses steel components instead of wood, concrete, or other materials. Steel structure is lighter, stronger, and more durable than traditional construction, and is also more cost-effective. Steel structure also requires less maintenance and is more resistant to fire, wind, and other natural disasters.

11.What certifications do your products have?

Providing safety and quality steel structure systems, ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.

12.What is the insulation and energy efficiency of light metal structure workshop?

We actively participate in the light metal structure workshop industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion Steel structure buildings are highly energy efficient and can be insulated to meet the highest energy efficiency standards. Steel is a great conductor of heat, so it is important to use insulation to reduce heat transfer. Steel structure buildings can be insulated with a variety of materials, including fiberglass, cellulose, and spray foam. Steel structure buildings can also be designed to meet the highest energy efficiency standards, such as LEED certification.

13.Are there different types of steel used in the construction of light metal structure workshop?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, there are different types of steel used in the construction of steel structure buildings. Common types of steel used include mild steel, high-strength steel, stainless steel, and galvanized steel. Each type of steel has its own unique properties and benefits, so it is important to choose the right type of steel for the specific application.

14.What are the design considerations for a light metal structure workshop?

We have a wide range of light metal structure workshop customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Iraq. 1. Structural Design: The structural design of a steel structure building should consider the building’s load-bearing capacity, the type of steel used, the size and shape of the steel members, and the connections between the members. 2. Architectural Design: The architectural design of a steel structure building should consider the building’s aesthetic appeal, the type of cladding used, the size and shape of the building, and the overall layout of the building. 3. Fire Protection: The fire protection of a steel structure building should consider the type of fire protection system used, the type of steel used, and the fire resistance rating of the steel. 4. Environmental Considerations: The environmental considerations of a steel structure building should consider the type of steel used, the type of insulation used, and the energy efficiency of the building. 5. Maintenance: The maintenance of a steel structure building should consider the type of steel used, the type of coating used, and the maintenance schedule for the building.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union